PTFE film is one of the most versatile high-performance engineering plastics used in modern industries.

While all PTFE films share the same base polymer, the manufacturing method significantly influences their physical characteristics, cost, and optimal use cases.

Among the most commonly used types are skived PTFE film, extruded PTFE film, and cast PTFE film.

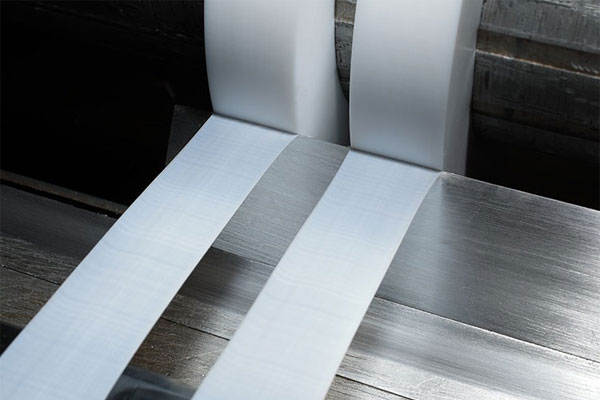

1. Skived PTFE Film

Skived PTFE film is produced by “skiving” a solid PTFE block, essentially peeling the material into thin sheets using a razor-like blade. The method is similar to slicing extremely thin layers from a log.

How Is Skived Film Made?

- PTFE resin is molded into a billet (block).

- The billet is sintered at high temperatures to fuse the polymer.

- Once hardened, it is mounted on a rotating mandrel.

- A precision blade skives sheets from the billet at controlled thicknesses.

Characteristics of Skived PTFE Film

- Wide thickness range, from ultra-thin (0.01 mm) to thick sheets (>3 mm).

- Excellent flexibility, due to its layered structure.

- High tensile strength in the skiving direction.

- Smooth surface finish with minimal defects.

- Light “grain direction” caused by the slicing motion.

Skived PTFE Film Advantages & Disadvantages

|

|

Common Applications

- Electrical insulation and capacitor films

- Gasket materials and seals

- Nonstick wrapping films

- Chemical lining and barrier layers

- Medical device components

- High-temperature masking tape (when adhesive-backed)

Skived PTFE film is the most widely used type because it provides an excellent balance of performance, versatility, and cost.

2. Extruded PTFE Film

Extruded PTFE film is manufactured by pushing PTFE paste resin through a die, producing continuous tapes or thin films with uniform thickness and exceptional tensile strength in the extrusion direction. It is commonly referred to as PTFE “paste-extruded film.”

How is Extruded PTFE Film Made?

- Fine PTFE powder resin is mixed with a lubricant to form paste.

- Paste is compressed into a preform.

- Preform is extruded through a die to create continuous film.

- Lubricant is removed via heat.

- Film is stretched (uniaxially or biaxially) to enhance mechanical properties.

Characteristics of Extruded PTFE Film

- High tensile strength, especially in the machine direction.

- Soft, flexible, and conformable film.

- Excellent dielectric properties.

- Continuous, seamless lengths without joints.

- Available in very thin gauges (from <0.02 mm).

Extruded PTFE Film Advantages & Disadvantages

|

|

Common Applications

- Wire and cable insulation

- Medical tubing reinforcement layers

- Stretchable membrane laminates

- Fuel cell membranes

- Aerospace insulation tapes

- High-performance sealing tapes

Extruded PTFE film is ideal when mechanical strength, stretchability, and continuous length are primary requirements.

3. Cast PTFE Film

Cast PTFE film is produced by chemically dispersing PTFE resin in a liquid medium to form an aqueous slurry. This slurry is then deposited onto a surface and dried, creating ultra-uniform films with isotropic properties.

Cast film is the only PTFE film that does not start as a solid billet or paste; instead, it begins as a PTFE dispersion, enabling extremely thin and highly consistent layers.

How Is Cast Film Made?

- PTFE resin is suspended in water to create a stable dispersion.

- The dispersion is cast onto a moving substrate (glass, metal, or polymer film).

- Water evaporates, leaving a PTFE film layer.

- The film is sintered at high temperature to fuse particles.

- Depending on the process, film can be laminated into multilayer structures.

Characteristics of Cast PTFE Film

- Extremely uniform thickness (micron-level control).

- No grain direction — isotropic structure.

- Excellent dielectric consistency.

- Ultra-thin films are possible, from <5 microns upward.

- Highly smooth and pristine surface.

Cast PTFE Film Advantages & Disadvantages

|

|

Common Applications

- Flexible printed circuits (FPC)

- Semiconductor manufacturing equipment

- Microwave and RF components

- Sensor diaphragms

- Precision medical films

- High-frequency wire insulation layers

Cast PTFE film is the top choice for electronics, semiconductors, and ultra-precision uses where consistency is critical.

Skived vs. Extruded vs. Cast PTFE Film: Comparison Table

| Property | Skived | Extruded | Cast |

|---|---|---|---|

| Thickness Range | Very wide | Thin to medium | Ultra-thin only |

| Mechanical Strength | Moderate | High | Moderate |

| Surface Finish | Very smooth | Smooth | Ultra-smooth |

| Grain Direction | Yes | Strong | None |

| Dielectric Uniformity | Good | Very good | Excellent |

| Max Roll Length | Medium | Very long | Medium |

| Cost | Most economical | Moderate–high | Highest |

| Best For | General industrial applications | High-strength, continuous rolls | Precision electronics |

Conclusion

PTFE films, whether skived, extruded, or cast, offer outstanding performance across a wide range of industries. However, the choice of film type depends heavily on the required properties:

- Skived PTFE film is the most versatile and economical, ideal for sealing, insulation, gasketing, and general industrial applications.

- Extruded PTFE film delivers superior tensile strength, stretchability, and long continuous lengths, making it excellent for wire insulation, aerospace components, and high-performance sealing tapes.

- Cast PTFE film provides unmatched thickness uniformity and dielectric precision, making it the top choice for semiconductor, microwave, and electronic circuit applications.

Understanding these distinctions helps manufacturers, engineers, and product designers make the best choice for performance, reliability, and cost efficiency in their applications.