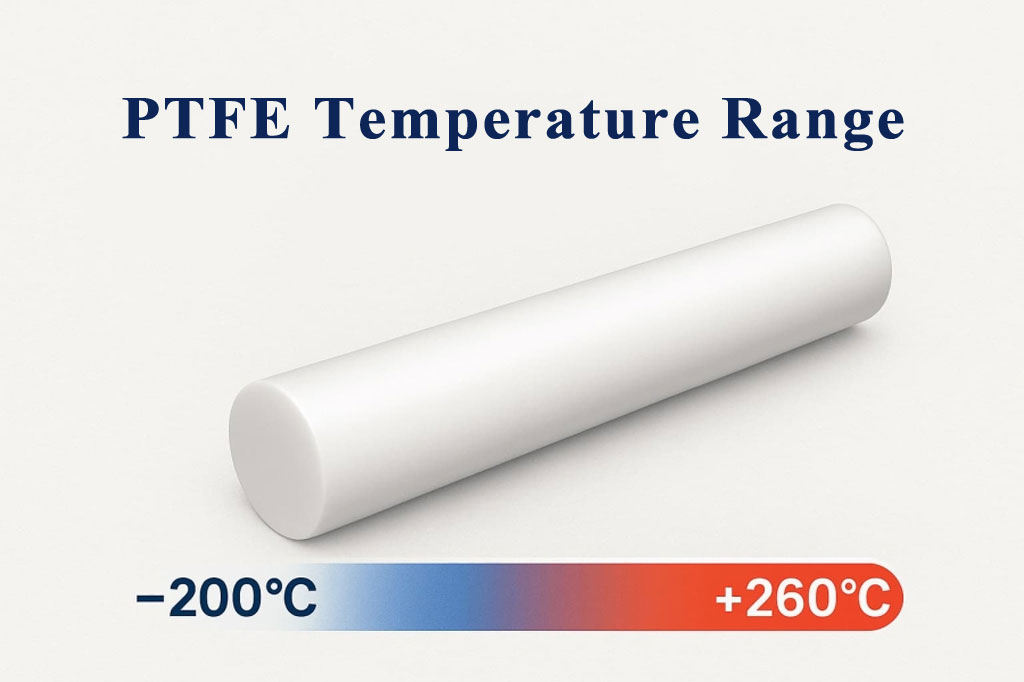

Among many attributes of PTFE, the temperature tolerance is a key factor that determines where and how it can be applied effectively.

For manufacturers and engineers, understanding PTFE’s temperature range is critical for designing components that perform reliably under extreme conditions.

PTFE Maximum Temperature

PTFE is remarkable for its ability to withstand high temperatures compared to most other polymers. In typical applications, virgin PTFE can operate continuously at temperatures up to 260°C (500°F) without significant degradation.

This high-temperature tolerance makes it suitable for use in:

- Industrial seals and gaskets in high-temperature piping systems.

- Insulation for wires and cables in electrical equipment exposed to heat.

- Chemical processing equipment that requires resistance to hot corrosive fluids.

It’s important to note that PTFE maintains its physical integrity at these temperatures but may experience slight dimensional changes. For applications above 260°C, specialized grades of PTFE with fillers like glass or carbon may be required to improve thermal stability.

PTFE Minimum Temperature

Equally impressive is PTFE’s performance at low temperatures. Unlike many other plastics that stiffen in low temperatures, virgin PTFE maintains its flexibility and toughness even at -200°C (-328°F).

This extreme low-temperature resilience makes PTFE ideal for:

- Cryogenic systems where materials must maintain integrity at near absolute zero temperatures.

- Cryogenic seals and gaskets in liquid nitrogen or helium systems.

- Arctic or high-altitude equipment where low temperatures are common.

PTFE’s low-temperature stability ensures that it remains reliable without cracking, chipping, or losing chemical resistance.

Temperature Effects on PTFE Performance

While PTFE has a wide temperature range, temperature does influence some of its mechanical and physical properties:

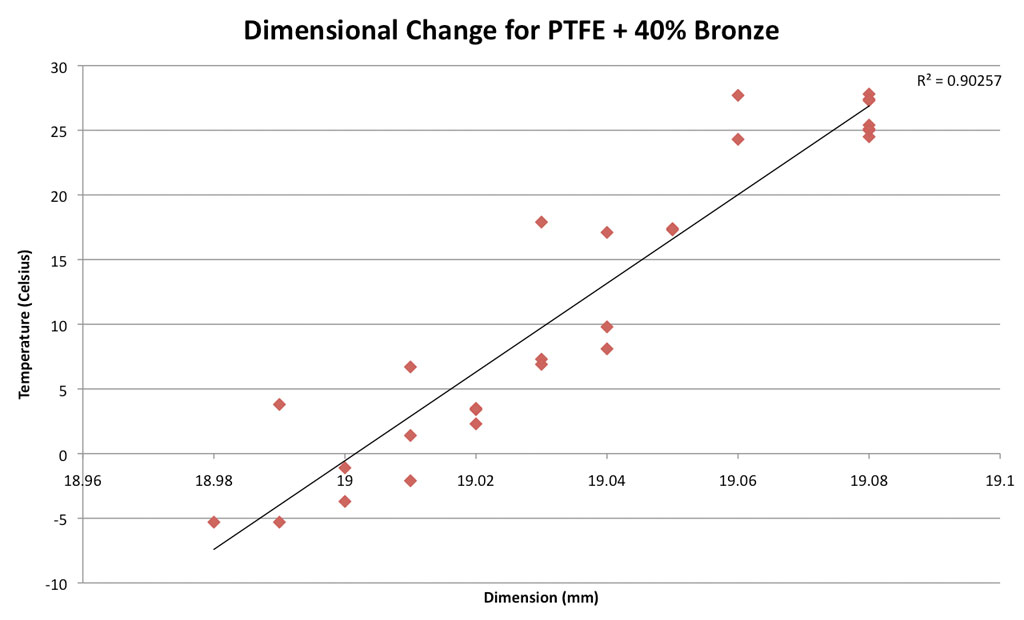

- Thermal Expansion: PTFE has a relatively high coefficient of thermal expansion, which means it expands and contracts significantly with temperature changes. Engineers must account for this when designing tight-tolerance components.

- Creep and Deformation: At elevated temperatures, PTFE can experience creep under constant load. For high-stress applications, filled PTFE grades (e.g., glass-filled) can reduce creep and improve dimensional stability.

- Mechanical Strength: Although PTFE remains chemically stable at high temperatures, its mechanical strength decreases slightly above 200°C. Design adjustments may be necessary in load-bearing applications.

- Thermal Conductivity: PTFE is a poor conductor of heat. At high temperatures, this can create localized hot spots if not properly managed in thermal applications.

Understanding these effects ensures that PTFE components continue to perform reliably across the entire temperature range.

PTFE Grades for Extreme Temperatures

To optimize PTFE for specific temperature applications, manufacturers often use modified or filled PTFE grades:

- Glass-Filled PTFE: Improves dimensional stability and reduces creep at high temperatures.

- Carbon-Filled PTFE: Enhances wear resistance and thermal stability for sliding or bearing applications.

- Mineral-Filled PTFE: Increases rigidity at both high and low temperatures while maintaining chemical resistance.

- Expanded PTFE (ePTFE): Porous form used for gaskets and membranes, offering flexibility and chemical resistance at extreme temperatures.

Selecting the appropriate PTFE grade ensures that the material performs optimally in the intended temperature environment.

Design Considerations for Temperature Applications

When using PTFE in temperature-sensitive applications, consider:

- Thermal Expansion Compensation: Allow for dimensional changes in assemblies.

- Stress Under Load: Use filled grades if the component is under continuous pressure at high temperatures.

- Chemical Exposure at Temperature Extremes: Verify chemical compatibility at both high and low temperatures.

- Installation Environment: Make sure PTFE components are kept within their recommended temperature limits.

Careful design ensures that PTFE’s superior properties are fully utilized without compromise.

Conclusion

PTFE is a unique polymer with an exceptionally wide temperature range, from -200°C (-328°F) to +260°C (500°F) in standard grades.

For high-temperature applications, filled PTFE grades can enhance performance, while low-temperature applications benefit from PTFE’s flexibility and toughness.