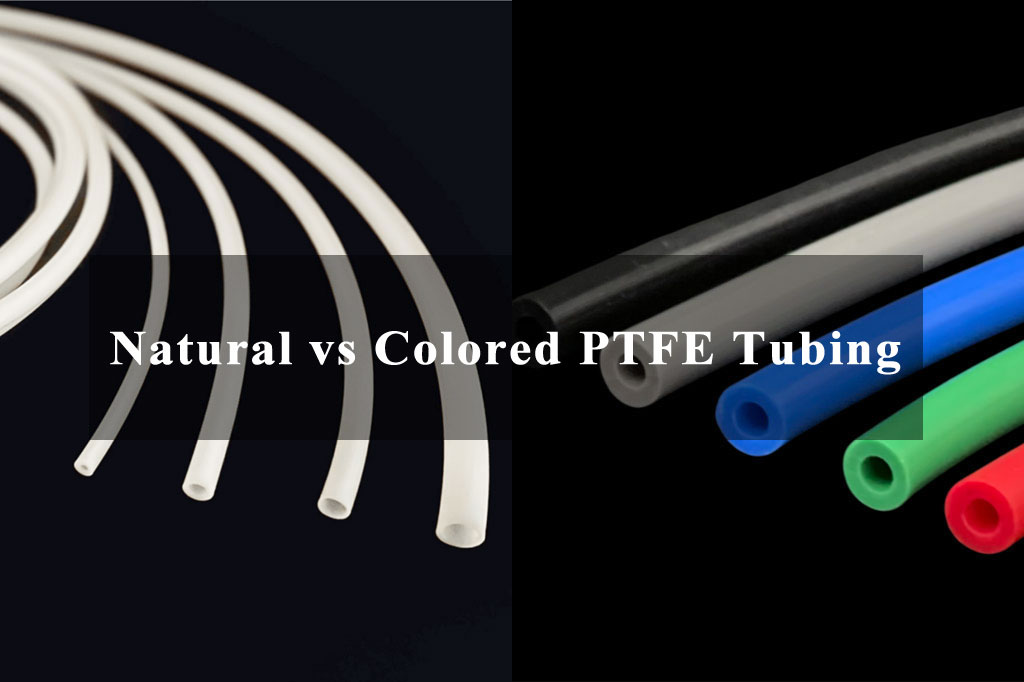

PTFE tubing is used for transporting corrosive chemicals, high-purity liquids, gases, and even solids in various industrial settings. It comes in different sizes, wall thicknesses, and forms (smooth bore, convoluted, heat shrinkable), and can be either natural or color-coded.

Our PTFE tubing is available in both natural (unpigmented) and colored variants, and while their base material remains the same, the choice between them can significantly affect functionality, visibility, and application suitability.

In this article, we’ll explore the key differences between colored and natural PTFE tubing, including their compositions, applications, benefits, and factors to consider when selecting the right type for your needs.

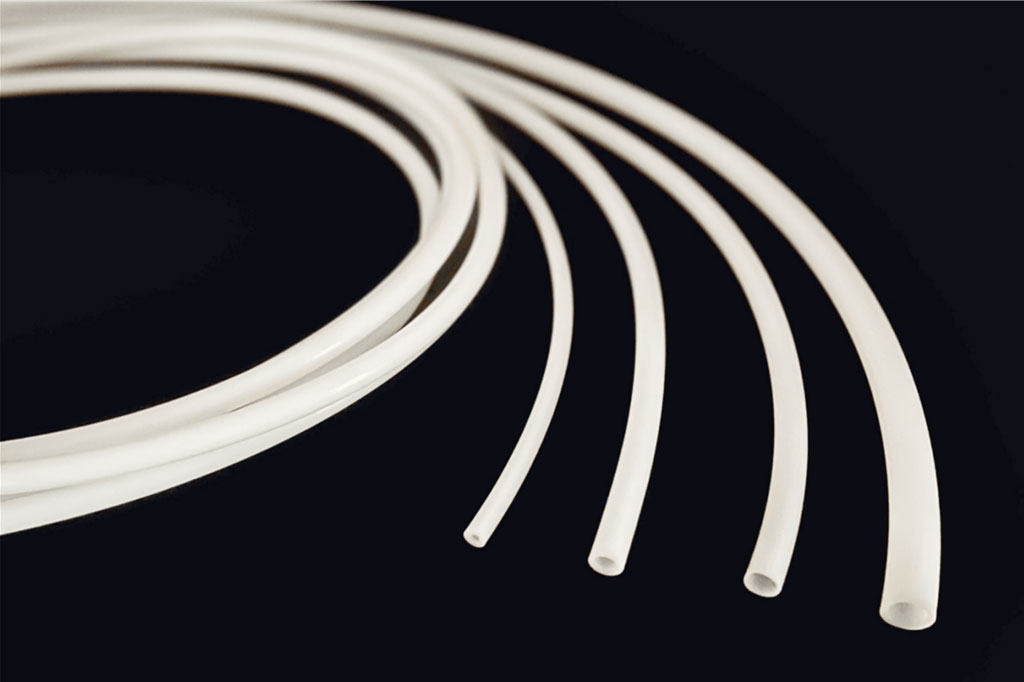

Natural PTFE Tubing

Natural PTFE tubing refers to the tubing in its unpigmented form, usually with a translucent white or milky appearance. It’s the purest form of PTFE without any color additives.

Key Characteristics:

- Appearance: Translucent to opaque white.

- Purity: High chemical and biological purity, suitable for sensitive applications.

- Chemical Resistance: Superior resistance to acids, bases, solvents, and reactive chemicals.

- Temperature Range: Withstands -200°C to 260°C (-328°F to 500°F).

- Mechanical Properties: Exhibits excellent tensile strength and a low friction coefficient.

Advantages:

- Ultra-high chemical and biological purity

- Ideal for sensitive or contamination-prone environments

- Lower cost in some cases

- Better for visual inspection of contents (slightly translucent)

Disadvantages:

- Lack of visual distinction in multi-tubing systems

- Not UV-resistant unless treated

Applications:

- Laboratory and medical equipment

- Semiconductor manufacturing

- Analytical instrumentation

- Food and beverage transfer

- Pharmaceutical fluid handling

Natural PTFE is often preferred when the tubing must not interact with the medium it transports, either chemically or visually. For example, in pharmaceutical or high-purity applications, even the slightest pigment or impurity may pose a contamination risk.

Colored PTFE Tubing

Colored PTFE tubing is made by adding FDA-compliant or industrial-grade pigments to the PTFE resin during the manufacturing process. It retains all the key properties of natural PTFE but adds visual identification and traceability advantages.

Key Characteristics:

- Appearance: Available in various colors such as red, blue, green, black, yellow, or custom colors.

- Visibility: Enhanced for quick identification of different lines, especially in complex systems.

- Functionality: Certain pigments provide added benefits like UV protection or electrical conductivity.

- Durability: Colored PTFE can sometimes exhibit slightly reduced purity due to pigment additives but still retains chemical and thermal performance.

Advantages:

- Color-coding improves safety and efficiency

- Easier system diagnostics and maintenance

- Some colorants add functionality (e.g., anti-static black PTFE)

- Better organization in complex environments

Disadvantages:

- Slightly lower purity due to pigments

- May not be suitable for ultra-pure or FDA-restricted applications

- Typically more expensive

Applications:

- Industrial process control

- Multiline systems in automation

- Color-coded chemical delivery systems

- Instrumentation and wiring insulation

- Aerospace and automotive industries

Colored PTFE tubing is particularly useful in environments where multiple lines need to be easily identified to avoid cross-contamination or connection errors.

Major Differences Between Colored and Natural PTFE Tubing

| Feature | Natural PTFE Tubing | Colored PTFE Tubing |

|---|---|---|

| Purity | Highest (no additives) | Slightly reduced due to pigments |

| Appearance | Translucent white | Wide range of colors |

| Visibility | Low; contents may be faintly visible | High; easy external identification |

| Applications | Ideal for medical, laboratory, high-purity uses | Ideal for industrial, control, and complex systems |

| Cost | Slightly lower | Slightly higher due to pigmentation |

| Customization | Limited | High (custom color-coding) |

| Contamination Risk | Minimal | Depends on pigment quality |

How to Choose Between Natural and Colored PTFE Tubing

- Application Purity Requirements:

If your application involves ultra-pure chemicals, pharmaceutical products, or medical use, natural PTFE is often the better choice due to its unmodified composition. - System Complexity:

For systems with multiple fluid lines or chemical feeds, color-coded tubing significantly reduces the chance of misidentification and accidents. - Regulatory Compliance:

Ensure the colored tubing uses FDA-approved pigments if used in food, medical, or pharmaceutical industries. - Environmental Conditions:

For outdoor or UV-exposed environments, pigmented tubing like black PTFE can provide better resistance to degradation. - Cost Efficiency:

While the cost difference is minimal, high-volume users may consider natural PTFE to save costs if color identification is not critical. - Customization Needs:

For unique projects or OEM solutions, colored PTFE offers options to differentiate lines by media type, flow direction, or safety level.