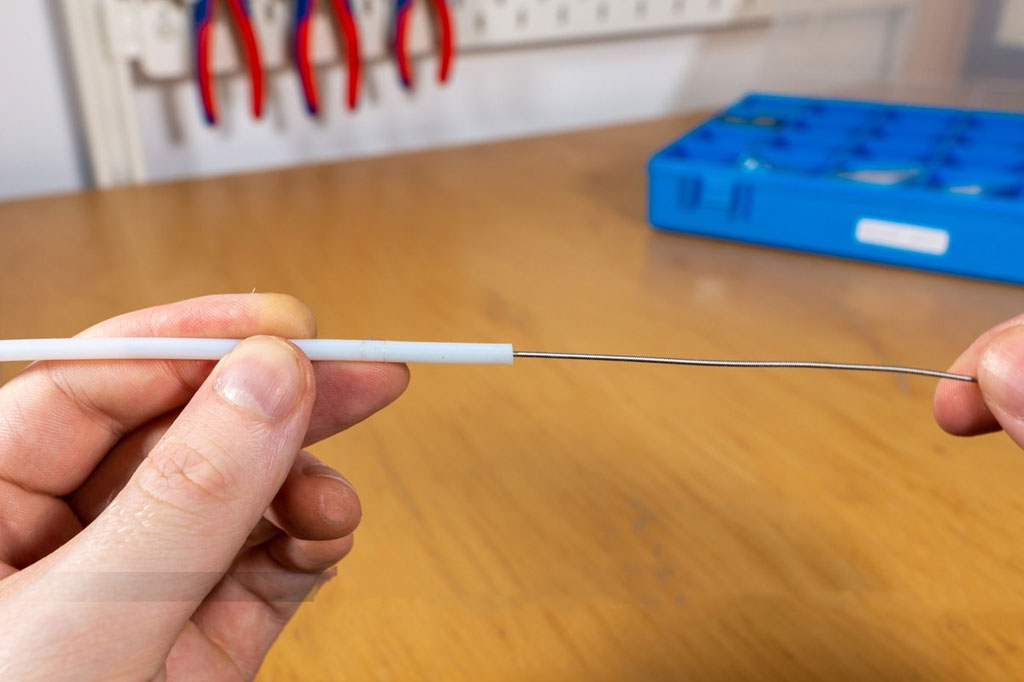

PTFE tubing is a versatile and widely used material known for its exceptional chemical resistance, high temperature tolerance, low friction, and non-stick properties.

However, one critical aspect that often causes confusion for engineers and procurement teams is tubing sizing standards, specifically, metric and imperial sizing systems.

In this article, we’ll break down the differences between metric and imperial PTFE tubing sizing, help you understand how to interpret these dimensions, and offer guidance on choosing the right type for your application.

Understanding PTFE Tubing Dimensions

Whether in metric or imperial units, PTFE tubing dimensions are generally described by three key measurements:

- Outer Diameter (OD): The outside diameter of the tubing.

- Inner Diameter (ID): The inside diameter through which fluids or gases pass.

- Wall Thickness: The difference between OD and ID divided by 2, indicating the strength and pressure rating.

Imperial PTFE Tubing Sizing

The Imperial system, widely used in the United States and a few other countries, measures tubing sizes in inches or fractions of an inch.

Typical Imperial sizes:

- 1/16″

- 1/8″

- 3/16″

- 1/4″

- 3/8″

- 1/2″

Imperial sizing often follows standards like AWG (American Wire Gauge) or OD-ID fractional sizing, and tolerances are based on inch-based precision systems (e.g., ±0.002″).

Example:

A 1/4” OD x 0.170” ID PTFE tube has a wall thickness of approximately 0.040”.

Applications: Imperial PTFE tubing is commonly found in:

- U.S.-made laboratory equipment

- Medical devices designed for FDA or USP standards

- North American industrial machinery

Metric PTFE Tubing Sizing

The Metric system uses millimeters (mm) and is prevalent in Europe, Asia, and most of the world.

Typical Metric sizes:

- 2 mm

- 4 mm

- 6 mm

- 8 mm

- 10 mm

- 12 mm

Metric sizing usually follows international standards like ISO 4063 or DIN, with tolerances such as ±0.1 mm.

Example:

A 6 mm OD x 4 mm ID PTFE tube has a wall thickness of 1 mm.

Applications: Metric PTFE tubing is common in:

- European and Asian automation systems

- International OEMs and global export equipment

- Pneumatic and fluid handling systems built to ISO norms

Key Differences Between Metric and Imperial PTFE Tubing

| Feature | Metric | Imperial |

|---|---|---|

| Unit of Measurement | Millimeters (mm) | Inches (in) |

| Regional Use | Europe, Asia, global | U.S., UK (some sectors) |

| Typical Sizing Examples | 6 mm OD x 4 mm ID | 1/4″ OD x 0.170″ ID |

| Tolerance Standards | ±0.05 mm to ±0.1 mm | ±0.002″ to ±0.005″ |

| Standards Followed | ISO, DIN | ASTM, SAE |

| Tubing Compatibility | Suited for metric fittings | Suited for NPT, SAE, or inch-based fittings |

| Conversion Required? | Rarely within global metric systems | Often needed when interfacing with metric parts |

Choosing the Right Sizing System

To avoid fitting mismatches, leaks, or system failures, it’s critical to choose the correct sizing system based on:

- End-Use Location: For products used in the U.S., imperial is usually preferred; for international products, metric may be more appropriate.

- Mating Components: Ensure tubing size matches connectors, fittings, and other parts to avoid misalignment or sealing problems.

- Standards Compliance: For applications requiring FDA, USP Class VI, or ISO compliance, sizing may influence material traceability and tolerances.

- Supplier Availability: Some suppliers specialize in one sizing system. Ensure they can deliver precise tolerances in the desired standard.

Conversion Tips

When switching between Metric and Imperial sizes, use the following conversions:

- 1 inch = 25.4 mm

- 1 mm = 0.03937 inch

Be cautious when converting — a 6 mm OD tube (~0.236”) does not exactly match a 1/4” OD tube (0.250”), which can cause issues with fittings or seals if mismatched.