When it comes to resin-based 3D printing, the choice of build surface or film at the bottom of the resin vat plays a critical role in print quality, durability, and maintenance.

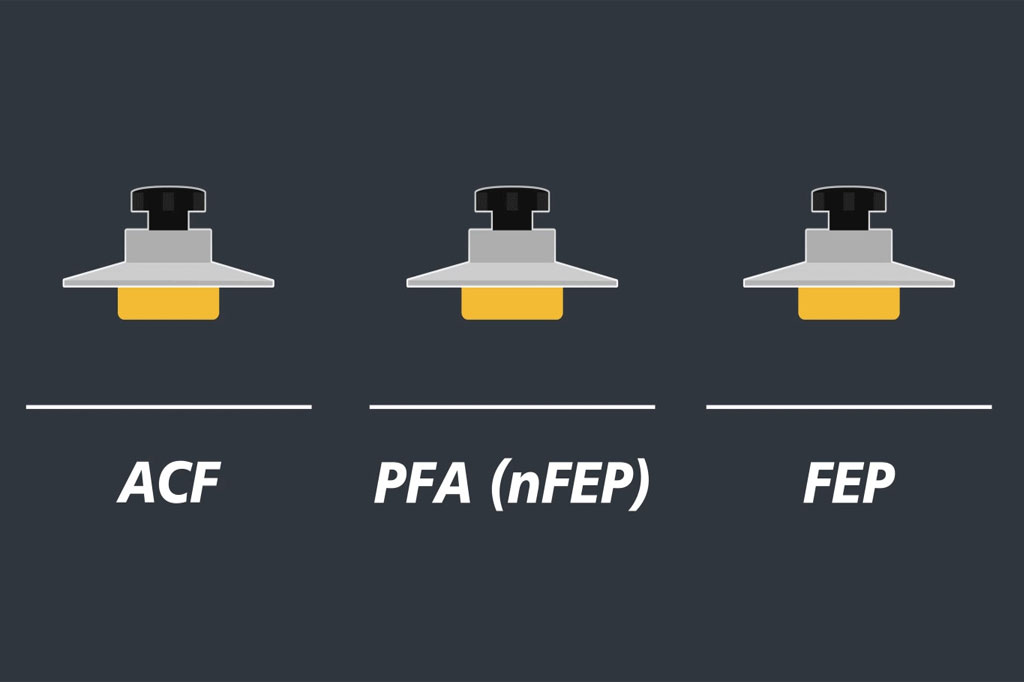

Three of the most commonly used materials are FEP (Fluorinated Ethylene Propylene) film, nFEP (also called PFA) film, and ACF (Anti-Corrosion Fluoropolymer) film.

While these films may seem similar at first glance, they differ significantly in chemical composition, mechanical properties, lifespan, and price.

Understanding their differences is crucial for 3D printing enthusiasts, professionals, and manufacturers seeking optimal results.

1. FEP Film

FEP film is the most widely used material in consumer and industrial resin 3D printers. It is renowned for its superior chemical resistance, low surface energy, and clear transparency. The low surface energy makes it ideal for resin printing because cured resin does not easily stick to it, allowing prints to separate cleanly from the film after each layer exposure.

Advantages of FEP Film:

- Affordability: FEP films offer an affordable option, making them a cost-effective choice for applications requiring frequent replacement.

- Good chemical resistance: It withstands most standard 3D printing resins without degradation.

- Ease of use: FEP films are compatible with most resin printers and provide consistent layer adhesion and release.

Disadvantages of FEP Film:

- Limited lifespan: Standard FEP films usually last between 50–100 print cycles, depending on resin type and print size.

- Susceptible to punctures: Thin FEP films can tear or develop holes, requiring careful handling during installation and cleaning.

- Slightly higher friction than PFA: While resin releases reasonably well, it may require occasional adjustment of print settings.

2. nFEP / PFA Film

nFEP, often marketed as PFA film, is a higher-end fluoropolymer variant with enhanced mechanical and thermal properties. Chemically similar to FEP, PFA offers lower surface friction, higher temperature resistance, and superior durability. nFEP is particularly favored in professional and industrial 3D printing applications where print consistency, minimal downtime, and material longevity are crucial.

Advantages of nFEP / PFA:

- Longer lifespan: nFEP films can endure hundreds of print cycles, often two to three times longer than standard FEP films.

- Lower surface friction: Resin release is smoother, reducing the risk of layer lifting or print failure.

- High-temperature tolerance: nFEP can handle resins cured at higher temperatures without warping or losing transparency.

- Chemical inertness: Extremely resistant to aggressive resins or specialty materials.

Disadvantages of nFEP / PFA:

- Higher cost: The advanced properties of nFEP come at a premium, making initial investment higher.

- Limited availability: While increasingly common, not all consumer printers offer ready-to-fit nFEP sheets.

- Potential overkill for casual printing: For hobbyists printing small models with standard resins, nFEP’s benefits may not justify the price.

3. ACF Films

ACF, or Anti-Corrosion Fluoropolymer films, are less common but offer a hybrid solution between FEP and PFA. These films are engineered for maximum chemical resistance, particularly for aggressive resins or industrial applications involving long print runs. ACF films combine transparency with a highly durable surface, making them suitable for printers handling specialty materials or continuous production setups.

Advantages of ACF Films:

- Exceptional chemical resistance: Ideal for highly reactive or filled resins that might degrade standard FEP or even PFA over time.

- Durability: Can endure frequent printing cycles without significant wear.

- Stable layer release: Maintains consistent print separation even with high-adhesion resins.

Disadvantages of ACF Films:

- High cost: Typically more expensive than both FEP and PFA films.

- Availability and compatibility: Often requires industrial printers or specific vat sizes.

- Less common: Users may find limited community support or replacement parts compared to FEP.

FEP vs nFEP vs ACF Films: Which is Best for 3D Printing?

The best film for 3D printing depends heavily on the type of printer, the resin used, the frequency of printing, and budget considerations. Here is a quick summary:

Feature | FEP Film | nFEP / PFA Film | ACF Film |

Cost | Low | Medium - High | High |

Lifespan | Short | Long | Longest |

Resin compatibility | Standard resins | Standard & specialty resins | Highly reactive/industrial resins |

Surface release | Good | Excellent | Excellent |

Temperature resistance | Moderate | High | High |

Availability | Widely available | Increasingly available | Limited |

Practical Recommendations:

- Hobbyists or casual users: Standard FEP film is usually sufficient. It provides reliable performance at an affordable price and is easy to replace.

- Professional or high-volume users: nFEP/PFA is the better choice for longevity, smoother release, and handling diverse resins without frequent replacement.

- Industrial or specialty applications: ACF films excel for aggressive, filled, or high-temperature resins and continuous printing setups.