Selecting the appropriate PTFE rod grade is crucial for balancing performance and cost. While virgin PTFE suffices for general-purpose applications, many demanding environments call for enhanced mechanical strength, improved stiffness, reduced wear, or better thermal conductivity.

Manufacturers achieve these improvements by compounding PTFE with fillers—glass fibers, bronze, carbon, graphite, molybdenum disulfide (MoS₂), and more.

In this article, we’ll explore the different grades of PTFE rods, including their compositions, properties, and common applications.

1. Virgin PTFE Rods

Virgin PTFE is the purest form of PTFE with no added fillers or reinforcements. It is manufactured using polymerization of tetrafluoroethylene without any additives.

Key Properties:

- Exceptionally low coefficient of friction (~0.05–0.10)

- High dielectric strength

- Chemically inert to nearly all substances

- Wide service temperature range (-200°C to +260°C)

- Non-stick and hydrophobic surface

- FDA-approved for food contact

Applications:

- Seals and gaskets

- Electrical insulators

- Food-grade components

- Medical devices

- Laboratory equipment

2. Reprocessed (Recycled) PTFE Rods

Reprocessed PTFE is made from scrap virgin PTFE that has been collected, cleaned, and re-molded or re-extruded. It typically has a grayish or off-white color compared to the bright white of virgin PTFE.

Key Properties:

- Lower cost than virgin PTFE

- Reduced purity and mechanical strength

- Slightly lower chemical resistance

- Not suitable for food or medical use

Applications:

- Non-critical components

- Spacers and bushings

- Industrial insulation

- Prototyping

3. Glass-Filled PTFE Rods

Glass-filled PTFE is reinforced with glass fibers (typically 5% to 25%) to enhance mechanical strength and dimensional stability.

Key Properties:

- Improved wear resistance and compressive strength

- Enhanced dimensional stability under load

- Reduced creep compared to virgin PTFE

- Slightly higher hardness

Applications:

- Valve seats

- Piston rings

- Bearings

- Structural components in chemical environments

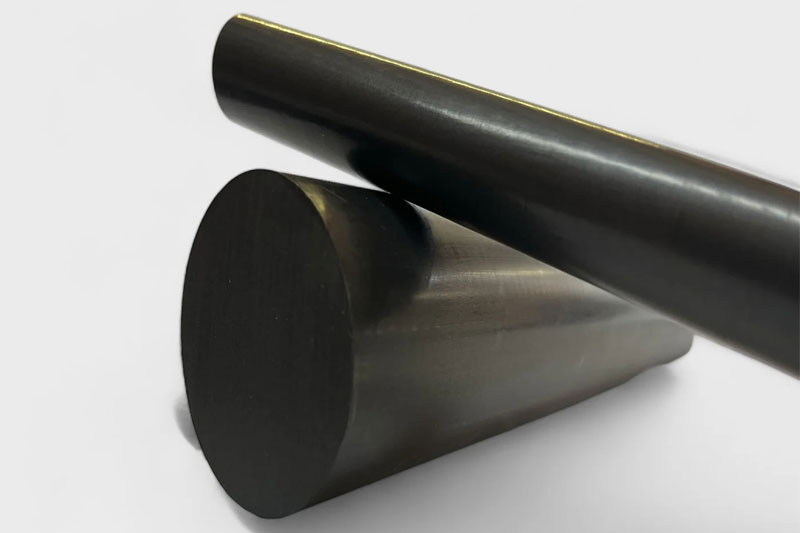

4. Carbon-Filled PTFE Rods

This grade includes carbon powder or graphite (usually 10% to 35%) as a filler, improving conductivity, hardness, and wear performance.

Key Properties:

- Enhanced wear resistance

- Good thermal conductivity

- Improved deformation resistance

- Lower friction in dry environments

Applications:

- Bearings and bushings in dry-running environments

- Sliding elements in pumps and compressors

- Anti-static applications

5. Bronze-Filled PTFE Rods

Bronze-filled PTFE incorporates finely powdered bronze (typically 40% or more), significantly increasing strength and wear resistance.

Key Properties:

- High load-bearing capacity

- Improved dimensional stability

- Good thermal conductivity

- Reduced chemical resistance compared to virgin PTFE

Applications:

- High-load bearings

- Wear rings and guide elements

- Hydraulic components

6. Molybdenum Disulfide (MoS₂)-Filled PTFE Rods

This specialty grade of PTFE includes molybdenum disulfide, which offers exceptional load-bearing and lubricating properties.

Key Properties:

- Enhanced wear and abrasion resistance

- Excellent dry lubrication

- High load-carrying capability

- Lower friction under load

Applications:

- High-performance sliding components

- Heavy-duty bearings

- Wear strips

7. PTFE with Polymer Fillers (e.g., PEEK, PI)

Blending PTFE with high-performance polymers like PEEK or polyimide can result in a composite material that retains PTFE’s low friction but gains strength and temperature resistance.

Key Properties:

- Superior mechanical strength

- Excellent thermal stability

- Enhanced chemical resistance

- High dimensional accuracy

Applications:

- Aerospace bushings

- Semiconductor processing equipment

- High-temperature sealing systems

Selecting the Right Grade for Your Application

Choosing the optimal PTFE rod grade involves balancing performance requirements, operating environment, and cost constraints. Below are key factors to consider:

Load and Wear

- For low-load, sliding applications (e.g., low-friction bushings), virgin or carbon-filled PTFE often suffices.

- For heavy loads or high abrasion, bronze-filled, MoS₂-filled, or graphite-filled grades provide superior wear life.

Dimensional Stability and Creep Resistance

- Applications demanding tight tolerances under static loads benefit from glass-filled or carbon-filled PTFE.

- If creep under compressive loads is a concern (e.g., seal rings), avoid virgin PTFE.

Thermal Management

- Bronze-filled PTFE offers enhanced thermal conductivity (around 0.5–1.5 W/m·K versus 0.25 W/m·K for virgin PTFE), allowing heat dissipation from hot surfaces.

- For high-temperature sliding contacts (e.g., bearings near 200 °C), graphite or MoS₂-filled grades maintain low friction.

Chemical Exposure

- In highly corrosive or highly pure environments (pharmaceutical, semiconductor), virgin or carbon-filled PTFE ensures maximum chemical inertness.

- Bronze or metal-filled grades risk corrosion or leaching if exposed to strong acids, bases, or ultra-pure water.

Electrical Properties

- For insulators, virgin or glass-filled PTFE provide dielectric strengths up to 60–80 kV/mm.

- When some conductivity or static dissipation is needed—e.g., electrode holders—carbon- or graphite-filled PTFE is preferable.

Cost Considerations

- Virgin PTFE typically is the most cost-effective.

- Filled grades incur a premium: glass-filled and carbon-filled are mid-range, whereas bronze or specialty composites command higher prices.

Comparison Chart of These Different Grades of PTFE Rod

| Grade | Filler Type | Color | Key Strengths | Limitations | Typical Applications |

|---|---|---|---|---|---|

| Virgin PTFE | None | White | Excellent chemical resistance, electrical insulation, low friction | Lower mechanical strength, cold flow | Food processing, medical, electrical insulation |

| Reprocessed PTFE | Recycled PTFE | Gray/Off-white | Cost-effective, suitable for non-critical uses | Reduced purity, not food/medical grade, lower strength | Prototypes, spacers, industrial bushings |

| Glass-Filled PTFE | 5–25% Glass fiber | Off-white/Grayish | Increased compressive strength, dimensional stability | Reduced flexibility, may abrade mating surfaces | Bearings, piston rings, valve seats |

| Carbon-Filled PTFE | 10–35% Carbon/Graphite | Black | Good thermal conductivity, wear resistance, anti-static | Slightly lower chemical resistance | Dry-running bearings, anti-static parts |

| Bronze-Filled PTFE | ~40% Bronze powder | Brownish | High load capacity, thermal conductivity | Reduced chemical resistance, heavier | Hydraulic systems, high-load bearings |

| MoS₂-Filled PTFE | Molybdenum disulfide | Dark gray | Excellent dry lubrication, load-bearing ability | Not ideal for corrosive chemicals | Heavy-duty bearings, wear strips |

| Polymer-Filled PTFE | PEEK, PI, etc. | Varies (usually dark) | High strength, heat resistance, stable dimensions | Higher cost | Aerospace, semiconductor equipment, high-temp seals |