PTFE bushings, also referred to as PTFE sleeves, are widely used in mechanical, automotive, chemical, and industrial systems where lubrication-free operation, reduced wear, and high temperature resistance are crucial.

PTFE bushings come in various types, primarily categorized by materials and design.

In this article, we’ll explore the most common types of PTFE bushings based on material composition and design & shape, to help engineers and procurement specialists make informed decisions.

I. Types of PTFE Bushings by Materials

PTFE bushings can be classified by their material composition, they can be divided into pure PTFE, filled PTFE, or PTFE-lined bushings, which greatly influences their mechanical performance, chemical resistance, and suitability for different operating environments.

1. Pure PTFE Bushing

Pure PTFE bushings are made entirely of virgin polytetrafluoroethylene without any fillers or additives. These bushings offer excellent non-stick characteristics, high resistance to chemicals, and operation across a wide temperature range from -200°C to +260°C.

Key Properties:

- Excellent chemical inertness

- Low friction coefficient (~0.05–0.1)

- Non-reactive to most acids and bases

- Great electrical insulating properties

- High compressibility but low mechanical strength

Applications:

- Chemical processing equipment

- Electrical insulation components

- Cryogenic systems

- Medical and food-grade machinery

Limitations:

Pure PTFE lacks mechanical strength and wear resistance, which may lead to deformation under load or prolonged use in high-pressure systems.

2. Filled PTFE Bushing

To improve mechanical and wear properties, PTFE is often filled with materials like glass fiber, carbon, graphite, bronze, or molybdenum disulfide (MoS₂). These filled PTFE bushings provide a balance between PTFE’s low-friction surface and enhanced strength, stiffness, and wear resistance.

Common Fillers and Their Effects:

- Glass Fiber: Enhances tensile strength and dimensional stability.

- Carbon: Improves compressive strength and conductivity.

- Graphite: Provides excellent self-lubrication and wear resistance.

- Bronze: Increases hardness and thermal conductivity.

- MoS₂: Reduces friction and enhances anti-wear properties.

Advantages:

- Better load-bearing capacity than pure PTFE

- Higher resistance to creep and wear

- Tailored properties for specific industrial needs

Applications:

- Automotive suspension and transmission systems

- Aerospace and military components

- Heavy machinery

- Pumps and compressors

Limitations:

Slightly reduced chemical resistance and electrical insulation compared to pure PTFE, depending on filler content.

3. PTFE Lined Bushing

PTFE-lined bushings are composite bushings featuring a metal backing (commonly steel or bronze) bonded with a thin PTFE lining or layer. This hybrid construction offers the strength and structural integrity of metal with the low-friction, self-lubricating surface of PTFE.

Key Properties:

- High load capacity due to metal backing

- Low friction surface reduces wear

- Ideal for dry, oil-free applications

- Reduced noise and vibration

Applications:

- Hydraulic cylinders

- Automotive steering and suspension

- Industrial robotics

- Marine equipment

Advantages:

- Excellent compromise between strength and lubrication

- Reduced maintenance and longer lifespan

- Good dimensional stability under load

Limitations:

More complex manufacturing process and slightly higher cost.

II. Types of PTFE Bushings by Design & Shape

Beyond material composition, PTFE bushings also come in various shapes and structural designs to accommodate different types of loads, installation methods, and mechanical requirements. The geometry of a bushing determines how it handles radial and axial forces, how easily it can be installed, and whether it can support precise alignment or field replacement. Common design types include cylindrical, flanged, and split bushings—each tailored to meet specific functional and spatial constraints across industries.

1. PTFE Cylindrical Bushing

Cylindrical PTFE bushings are straight-sleeve bushings with a uniform outer diameter and a hollow inner section for shaft insertion. This is the simplest and most common design for rotary and sliding applications.

Key Features:

- Simple, compact shape

- Easy to install and replace

- Can be made from pure or filled PTFE

Applications:

- Rotary shafts and axles

- Conveyor rollers

- Actuators and motors

- Low-load pivot joints

Advantages:

- Cost-effective

- Versatile across industries

- Suitable for radial load applications

Limitations:

Not ideal for axial loads or applications requiring additional alignment or load distribution.

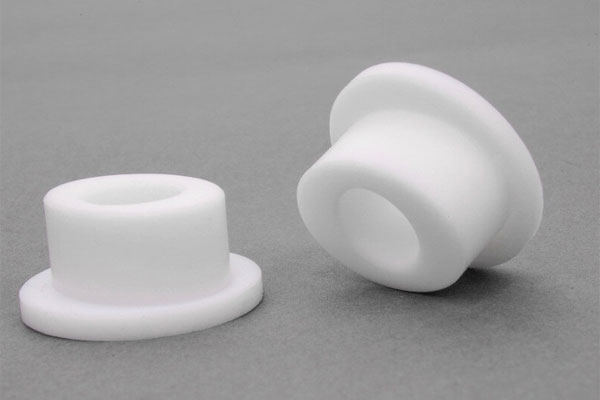

2. PTFE Flanged Bushing

A flanged PTFE bushing includes an integrated flange—usually on one end—which serves to support axial loads and aids in accurate alignment. The flange also prevents the bushing from moving axially during operation.

Key Features:

- Flange helps in positioning and retention

- Enhanced axial load support

- Available in various flange sizes and shapes

Applications:

- Pulleys and sheaves

- Gear housings

- Hinges and articulated arms

- Suspension systems

Advantages:

- Better retention and ease of assembly

- Dual load support: radial and axial

- Reduces need for additional fastening hardware

Limitations:

Requires more space than cylindrical bushings; slightly more expensive due to additional material and machining.

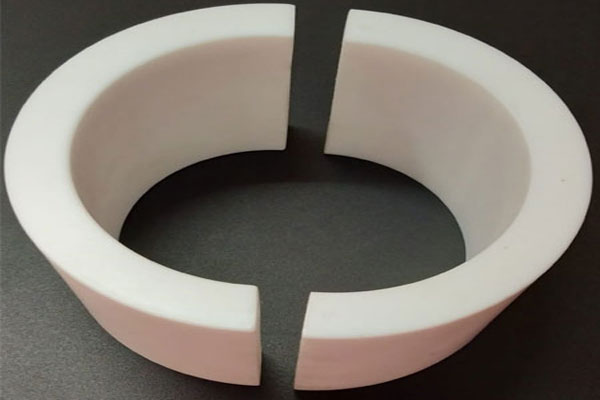

3. PTFE Split Bushing

Split PTFE bushings (also called slotted or wrapped bushings) feature a cut or slot along their length, allowing them to flex open slightly during installation. This makes them ideal for press-fit applications and easy field replacement without complete disassembly.

Key Features:

- Slot provides flexibility for compression fit

- Self-retaining in boreholes

- Can accommodate minor shaft misalignments

Applications:

- Automotive door hinges

- Agricultural and mining machinery

- Temporary or emergency repairs

- Appliances and consumer electronics

Advantages:

- Easy installation and replacement

- Ideal for field service and maintenance

- Accommodates minor shaft diameter variations

Limitations:

Lower load capacity compared to seamless bushings; not suitable for high-speed or precision applications due to possible vibration.