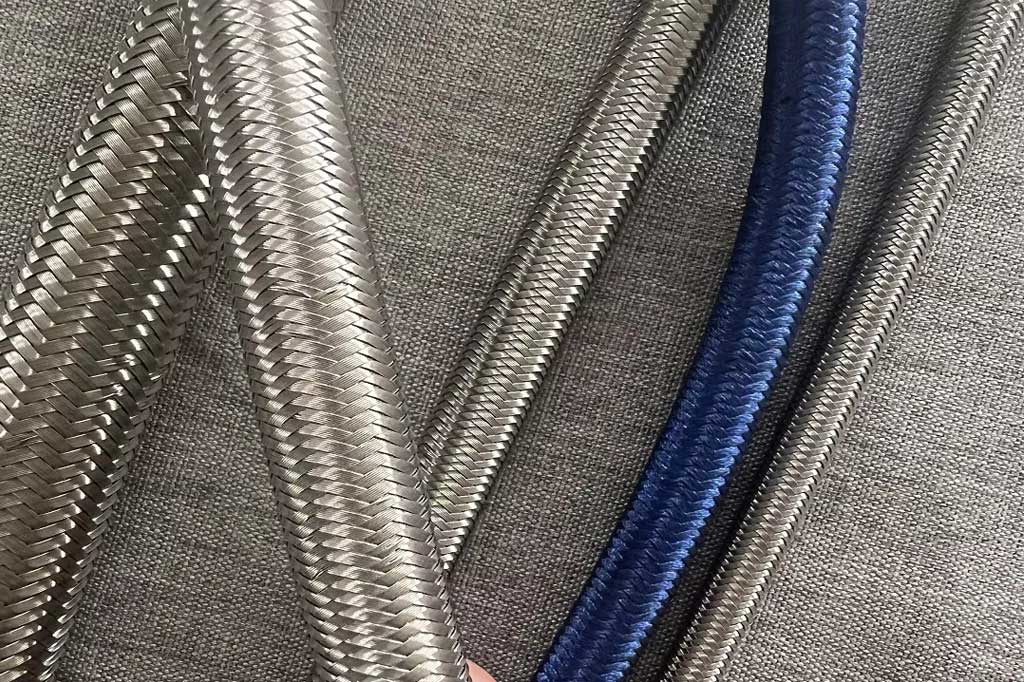

To enhance its mechanical strength, pressure resistance, and flexibility, PTFE tubing is often reinforced with braiding materials, such as stainless steel, polyester, fiberglass, aramid fiber, nylon, etc.

These materials serve as a support layer, helping the tubing withstand higher internal pressures and resist kinking or deformation under dynamic conditions.

In this article, we will explore the 6 most common braiding materials used for reinforced PTFE tubing, including their properties, applications, and advantages.

1. Stainless Steel Wire Braid

Stainless steel is one of the most common and durable materials used for braiding around PTFE tubing.

Key Properties:

- High tensile strength

- Excellent corrosion resistance

- Withstands high temperatures (up to 260°C / 500°F)

- Maintains structural integrity under high pressure

Applications:

- Hydraulic systems

- Steam transfer lines

- High-pressure gas and fluid transfer

- Chemical transport in harsh environments

Advantages:

- Provides excellent mechanical protection

- Compatible with aggressive chemicals

- Long service life

2. Polyester Yarn Braid

Polyester braiding offers a lightweight and flexible reinforcement option for PTFE tubing, especially when cost and weight are critical.

Key Properties:

- Good abrasion resistance

- Moderate temperature tolerance (up to 150°C / 302°F)

- UV-resistant

- Chemical-resistant to many substances

Applications:

- Beverage and food processing

- Low to medium pressure pneumatic systems

- Medical device tubing

Advantages:

- Economical

- Good flexibility

- Easy to handle and install

3. Fiberglass Braid

Fiberglass braiding is ideal for applications requiring thermal insulation and high-temperature resistance.

Key Properties:

- High-temperature resistance (up to 650°C / 1200°F)

- Non-flammable

- Electrical insulation capabilities

Applications:

- High-temperature gas and steam transfer

- Thermal insulation layers

- Aerospace and automotive heat shielding

Advantages:

- Maintains strength under extreme heat

- Provides thermal protection

- Excellent electrical insulation

4. Kevlar® (Aramid Fiber) Braid

Kevlar®, a registered trademark of DuPont, is an aramid fiber known for its exceptional strength-to-weight ratio and thermal stability.

Key Properties:

- 5 times stronger than steel by weight

- High pressure resistance

- High-temperature tolerance (up to 260°C / 500°F)

- Excellent chemical resistance

Applications:

- Hydraulic lines in aerospace

- Military and defense equipment

- High-pressure fluid systems

Advantages:

- Ultra-lightweight with high durability

- Superior fatigue resistance

- Flame resistant and low smoke output

5. Nylon Braid

Nylon is a flexible synthetic polymer that is commonly used for lower-pressure PTFE tubing applications.

Key Properties:

- Lightweight and flexible

- Temperature resistance up to 120°C / 248°F

- Good impact and abrasion resistance

Applications:

- Pneumatic systems

- Food-grade tubing

- General-purpose fluid transport

Advantages:

- Cost-effective

- Easy to install and route

- Available in various colors for coding

6. Monofilament PET (Polyethylene Terephthalate) Braid

PET monofilament offers a strong yet lightweight reinforcement for PTFE tubing with good chemical and abrasion resistance.

Key Properties:

- Excellent flexural strength

- Temperature resistance up to 150°C / 302°F

- Resistant to moisture and chemicals

Applications:

- Electronics and data transfer protection

- Beverage and chemical dispensing

- Automotive wire and fluid protection

Advantages:

- Lightweight and non-corrosive

- Cost-effective alternative to metal braiding

- High abrasion resistance

Choosing the Right Braiding Material

When selecting a braiding material for reinforced PTFE tubing, consider the following factors:

| Criteria | Important Considerations |

|---|---|

| Operating Pressure | Stainless steel or Kevlar® for high pressure |

| Temperature Range | Fiberglass or Kevlar® for high heat environments |

| Chemical Compatibility | Stainless steel or PTFE-coated materials |

| Weight Requirements | Nylon or Kevlar® for lightweight applications |

| Flexibility Needs | Polyester or nylon braiding |

| Cost Constraints | Nylon or polyester for budget-sensitive uses |