Understanding the Shrink Ratio in PTFE Heat Shrink Tubing

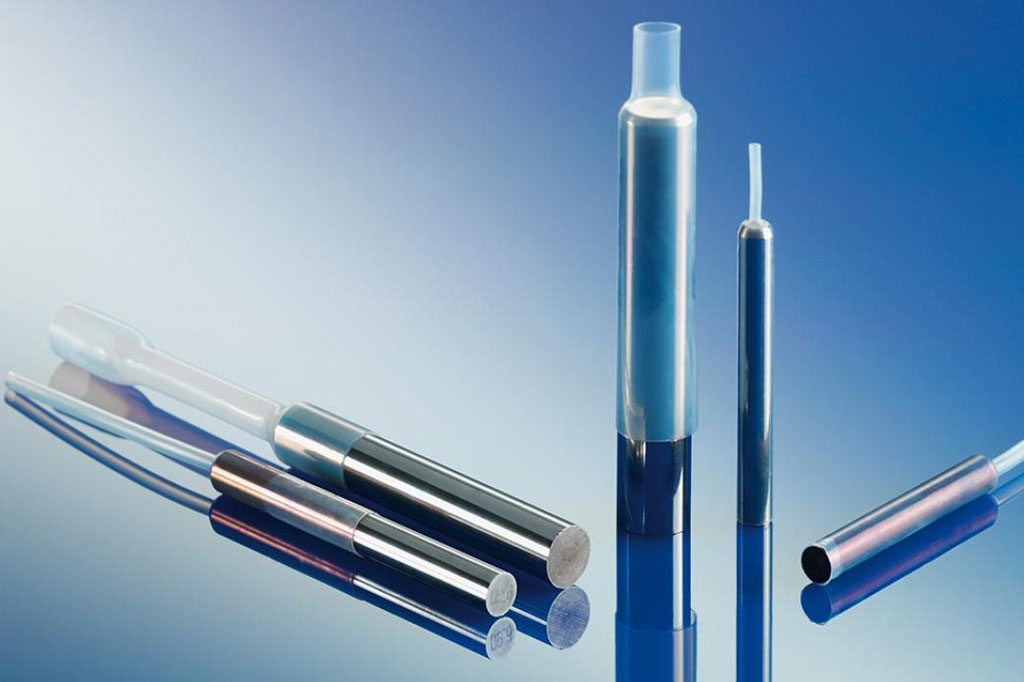

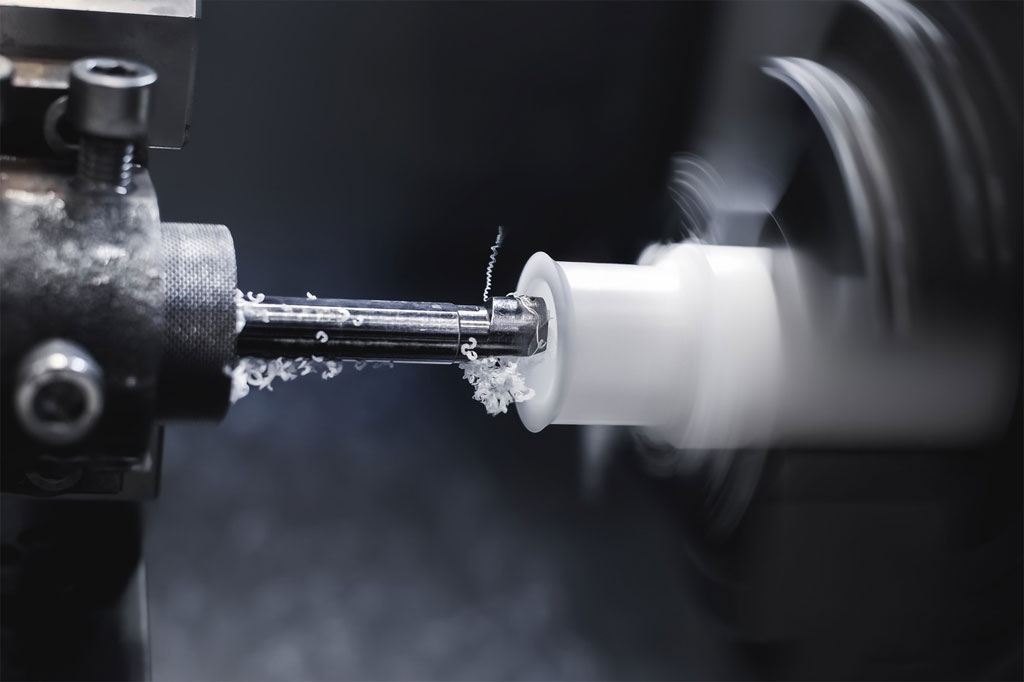

PTFE heat shrink tubing is a high-performance solution used in industries ranging from aerospace and automotive to electronics and medical devices. One of the key properties of this tubing that determines its suitability for specific applications is its shrink ratio. Understanding the shrink ratio helps engineers and manufacturers ensure a proper fit, effective insulation, and optimal […]

Understanding the Shrink Ratio in PTFE Heat Shrink Tubing Read More »