Polytetrafluoroethylene (PTFE) is a highly versatile fluoropolymer widely used in industries ranging from chemical processing to electronics. One of its most notable characteristics is its high thermal stability, which is mainly defined by its melting point.

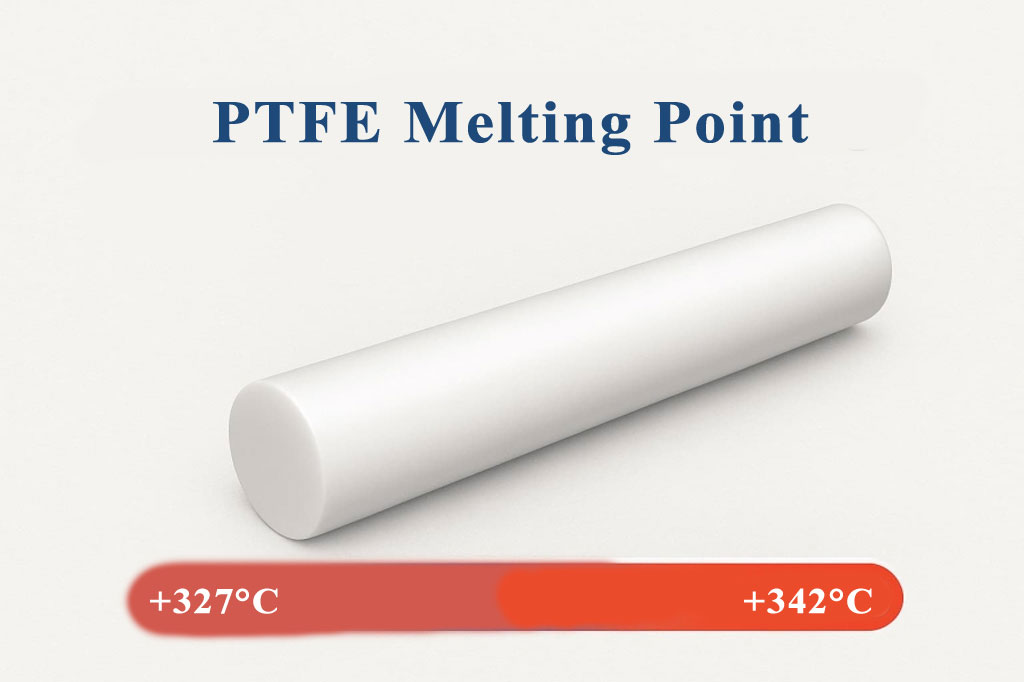

PTFE does not have a sharp melting point like crystalline metals; instead, it exhibits a melting range, typically between 327°C and 342°C (620°F–648°F).

Why PTFE Have a High Melting Point Range?

Unlike many polymers, PTFE maintains its structural integrity over a wide temperature range. This high melting range makes it suitable for environments where other plastics would degrade, soften, or lose functionality.

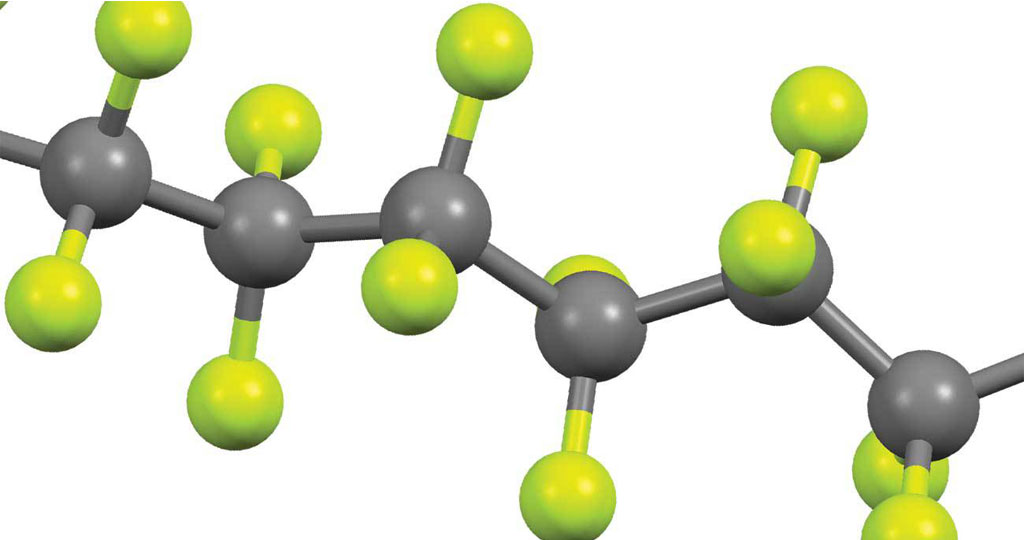

Its unique molecular structure – long chains of carbon atoms fully fluorinated, gives it strong C-F bonds, contributing to its high melting behavior and low coefficient of friction.

Factors Affecting PTFE Melting Behavior

The melting behavior of PTFE can vary based on several key factors:

- Molecular Weight: PTFE is available in different molecular weight grades. Higher molecular weight PTFE typically exhibits higher melting points due to increased chain entanglement, which provides greater thermal resistance.

- Crystallinity: The degree of crystallinity significantly affects PTFE’s thermal characteristics. Highly crystalline PTFE tends to have a sharper melting range and better thermal stability, whereas less crystalline PTFE may display a broader melting range.

- Additives and Fillers: Filled PTFE compounds, such as those reinforced with glass, carbon, or graphite, can slightly alter the melting behavior. While fillers improve mechanical properties, wear resistance, and dimensional stability, they can also influence thermal conductivity and localized melting characteristics.

- Processing Conditions: The way PTFE is processed—through extrusion, molding, or skiving—can impact its crystallinity and molecular orientation, thereby affecting its melting profile. Controlled heating and cooling during manufacturing ensure consistent melting behavior and product quality.

- Impurities: Even minor contamination can influence melting behavior. High-purity PTFE ensures a reliable and predictable melting range, which is especially critical in high-performance or medical applications.

Practical Considerations for Manufacturers

For manufacturers working with PTFE, several practical aspects should be considered:

- Controlled Heating: PTFE processing often involves heating close to its melting range, such as during sintering or molding. Control the temperature precisely, which is crucial to avoid overheating, which can compromise mechanical properties.

- Cooling and Annealing: After heating, PTFE components should be cooled gradually to prevent internal stresses and ensure dimensional stability. Annealing helps stabilize the crystalline structure and improves resistance to deformation under heat.

- Selection of PTFE Grades: Manufacturers should choose the appropriate grade of PTFE for each application. High-purity or virgin PTFE may be preferred for critical components, while filled PTFE compounds provide enhanced wear resistance for mechanical parts.

- Quality Control: Consistent melting behavior is a quality indicator. Regular testing, including differential scanning calorimetry (DSC), ensures that PTFE batches meet the required thermal specifications.

- Application-Specific Design: When designing components, factors such as maximum operating temperature, thermal cycling, and load conditions must be considered. Proper knowledge of PTFE melting behavior allows for accurate tolerance design and reliable performance.