FEP (Fluorinated Ethylene Propylene) film plays a crucial role in resin-based 3D printing, particularly in SLA (Stereolithography) and MSLA (Masked Stereolithography) printers. It acts as a non-stick layer between the cured resin and the bottom of the resin vat, allowing prints to release cleanly.

Despite its critical function, FEP film can develop issues over time, impacting print quality and consistency.

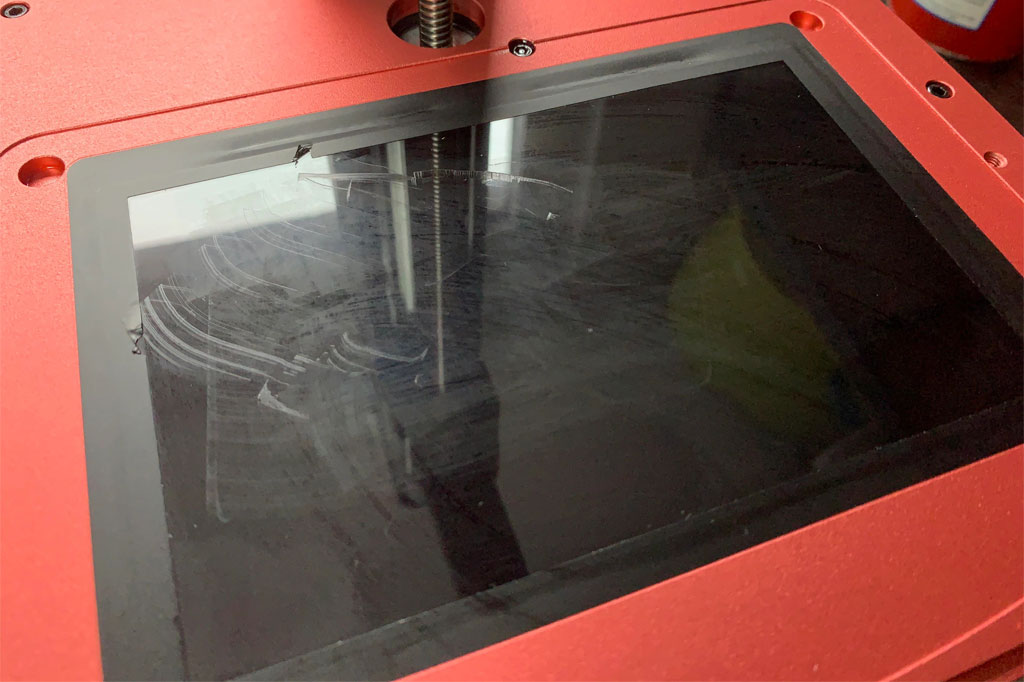

1. Scratches or Abrasions on the FEP Film

Scratches on the FEP film can occur during print removal, improper cleaning, or accidental contact with tools. These scratches can create adhesion inconsistencies, leading to failed prints or imperfections in the first layers.

Solution:

- Inspect the FEP film regularly for scratches.

- Replace the FEP sheet if scratches are deep or extensive.

- Use soft tools, like plastic spatulas, when removing prints.

- Avoid sharp objects or abrasive cleaning materials when cleaning the vat.

2. Cloudiness or Fogging

Over time, FEP film can become cloudy or develop a frosted appearance due to repeated UV exposure and resin interaction. This reduces light transmission, affecting the curing process and print accuracy.

Solution:

- Replace the FEP film once cloudiness becomes noticeable.

- Clean the film gently with isopropyl alcohol (IPA) to remove resin residue.

- Avoid prolonged exposure to direct sunlight to minimize UV degradation.

- Consider investing in thicker or higher-quality FEP films that resist clouding.

3. Resin Sticking to the FEP Film

If the cured resin sticks too aggressively to the FEP film, it can tear the film or distort the print when removing it. This often happens when the FEP is old, stretched, or has surface damage.

Solution:

- Check for film tension; loose films increase sticking risks. Retighten or adjust the vat screws to achieve proper tension.

- Replace worn or damaged FEP films.

- Ensure resin is compatible with your FEP film. Some resins are more aggressive and may require specific FEP types.

- Apply a thin layer of resin leveling or use a release agent if necessary (check resin manufacturer recommendations).

4. FEP Film Punctures or Tears

Accidental punctures or tears can occur during print removal or from foreign objects in the vat. Even small tears compromise the non-stick surface, causing print failures and resin leakage.

Solution:

- Handle prints carefully with soft, flexible spatulas.

- Always check for foreign particles or hardened resin fragments in the vat before printing.

- Replace the FEP film immediately if any puncture or tear occurs.

- Consider using reinforced or multi-layer FEP films for high-stress applications.

5. Improper FEP Tension

Incorrect tension – either too tight or too loose – can cause prints to fail. Loose FEP leads to wrinkles, while over-tightening can increase stress, causing premature film failure.

Solution:

- Follow the printer manufacturer’s guidelines for correct FEP tension.

- Perform periodic tension checks and adjust screws evenly around the vat.

- Ensure the film is uniformly flat without bubbles or waves.

6. Chemical Degradation

FEP can degrade over time when exposed to certain aggressive resins or cleaning chemicals. Signs include brittleness, discoloration, or surface irregularities.

Solution:

- Only use recommended cleaning agents, such as isopropyl alcohol or mild detergents. Avoid acetone or harsh solvents.

- Limit prolonged resin exposure; clean the vat and FEP film regularly.

- Replace FEP films periodically, depending on usage frequency and resin types.