PTFE tubing is not a one-size-fits-all product. Different variants of PTFE tubing exist, each tailored for specific use cases based on its manufacturing process, design characteristics, and intended performance.

Today, we’ll explore the different available types of our PTFE tubing, their structural and material differences, advantages, limitations, and application areas across various industries

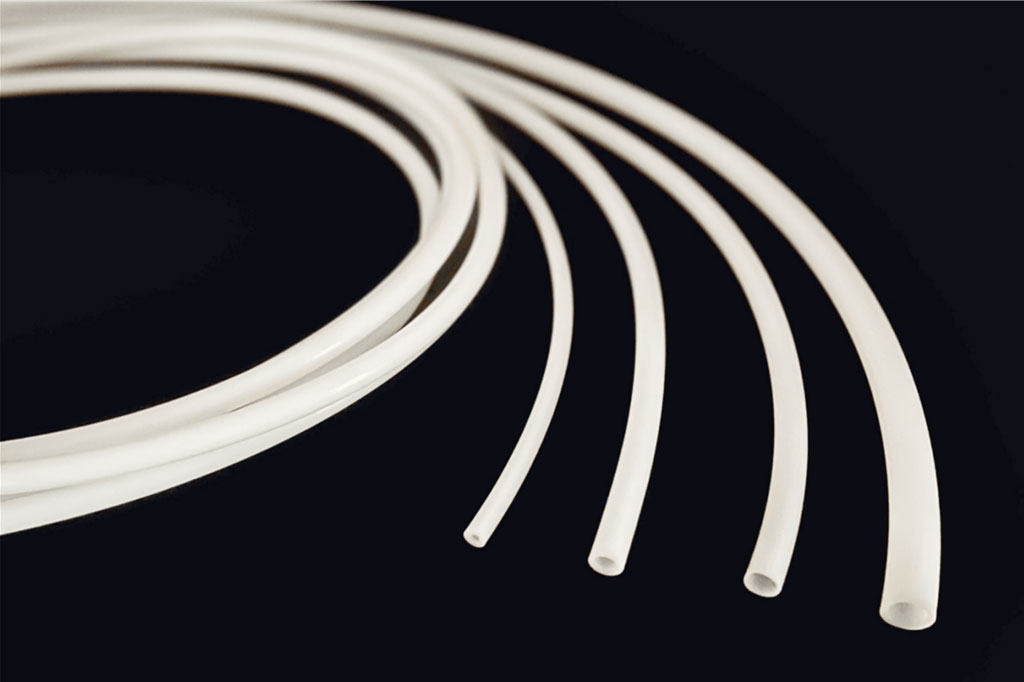

1. Natural PTFE Tubing

Natural or virgin PTFE tubing is the unmodified form of PTFE and is typically white or semi-translucent. It’s the baseline against which other variants are compared.

Key Properties:

- Chemically inert to almost all industrial chemicals

- Extremely high thermal stability (-200°C to +260°C)

- Non-wetting and non-stick surface

- Electrically insulating and UV resistant

- Low permeability to gases

Manufacturing Methods:

- Ram Extrusion: Used for larger-diameter and thicker-walled tubing.

- Paste Extrusion: Ideal for thin-walled and flexible tubing with smaller diameters.

Applications:

- Laboratory equipment (sample transfer lines)

- Pharmaceutical processing

- High-purity water systems

- Electrical insulation in aerospace and automotive

Limitations:

- Can be rigid and hard to bend unless thin-walled

- Not suitable for high-pressure or dynamic movement without reinforcement

2. Colored PTFE Tubing

Colored PTFE tubing adds pigmentation to differentiate lines or signal flow paths, especially in complex systems involving multiple chemical or fluid transfer lines.

Common Colors:

- Red

- Blue

- Yellow

- Green

- Black

- Custom colors on request

Use Case Example:

In a pharmaceutical cleanroom, red tubing may denote an acid line, blue for base, and green for purified water. This minimizes cross-contamination and improves operational safety.

Key Benefits:

- Enhances line visibility

- Reduces installation errors

- Aesthetic appeal in consumer or laboratory setups

Drawbacks:

- Colorants may slightly reduce thermal or chemical resistance

- Typically not used in ultrapure or medical-grade environments

3. Convoluted PTFE Tubing

Convoluted PTFE tubing has a corrugated wall structure, allowing it to bend easily without kinking. The design adds flexibility while retaining many of the material’s original benefits.

Features:

- High flex-life

- Excellent bend radius

- Can be coupled with braids or liners for higher performance

Applications:

- Movable joints in robotic arms

- Semiconductor fabrication

- Flexible connections in chemical plants

Advantages:

- Designed for dynamic motion and vibration damping

- Customizable with cuffs and flares for easy fittings

Limitations:

- Reduced internal smoothness may hinder flow of viscous materials

- Slightly higher cost and complex fabrication process

4. Heat Shrinkable PTFE Tubing

Heat shrink PTFE tubing is engineered to contract under high heat, forming a tight, protective seal around wires, components, or splices. Shrinking creates a protective layer that’s both chemically inert and thermally stable.

Shrink Ratios:

- 2:1 (shrinks to half its original diameter)

- 4:1 (shrinks to a quarter)

Applications:

- Wire harnessing in aerospace

- Component protection in high-voltage systems

- Encapsulation of thermally sensitive sensors

Benefits:

- Clean finish with permanent protection

- Maintains flexibility even after shrinking

- Resistant to corrosive environments

Installation Notes:

- Requires controlled heating, typically using a hot air gun or oven

- Avoid open flames to prevent carbonization

5. Dual-Layer PTFE Tubing

Dual-layer tubing involves a PTFE inner layer with an outer layer made from another fluoropolymer like FEP (fluorinated ethylene propylene) or PFA (perfluoroalkoxy alkane).

Advantages:

- Combines different performance characteristics

- Easier bonding and sealing with external components

- Improved clarity or structural strength

Applications:

- Medical catheter linings (lubricated PTFE core)

- Semiconductor transport tubing

- Analytical instrumentation lines

Customization:

Some variants also include an adhesive or tie-layer to allow overmolding or encapsulation for advanced assemblies.

6. PTFE Spiral Tubing

Spiral PTFE tubing is manufactured in a coil-like shape and designed to stretch and retract, ideal for applications requiring mobility and compact installation.

Key Features:

- Spiral memory for repeated extension

- Durable and abrasion resistant

- Available in various extension lengths and diameters

Use Cases:

- Automation systems with mobile actuators

- Pneumatic tool lines

- Coiled fluid delivery in laboratory setups

Pros:

- Excellent space utilization

- Minimizes risk of tubing entanglement

- Shock-absorption for fragile systems

7. Filled PTFE Tubing

To overcome some mechanical limitations of virgin PTFE, fillers are added to create reinforced variants. These improve wear resistance, reduce deformation, and add strength.

Common Fillers:

| Filler | Benefits | Applications |

|---|---|---|

| Glass fiber | Enhances stiffness and creep resistance | Valve seats, seals |

| Carbon | Increases wear resistance and conductivity | Bearings, ESD-safe tubing |

| Graphite | Adds lubricity for lower friction | Dry-running seals |

| Bronze | Improves compressive strength | High-load components |

Trade-offs:

- Slight reduction in chemical resistance

- May increase material density

- Can introduce particulates (not for ultrapure systems)

8. Expanded PTFE Tubing (ePTFE)

ePTFE is made by expanding PTFE under pressure and heat, creating a porous structure while maintaining chemical inertness. It’s soft, compressible, and ideal for filtering or sealing.

Unique Characteristics:

- Microporous and breathable

- Soft and pliable

- Excellent compression recovery

Applications:

- Medical implants (vascular grafts, sutures)

- Vent membranes in electronic casings

- Gaskets and sealing tape

Performance Profile:

- Excellent gas permeability

- Hydrophobic and oleophobic properties

- Long-term durability under dynamic pressure

9. PTFE Tubing with Braided Reinforcement

This variant is designed for high-pressure and high-flex environments. A stainless steel, polyester, or Kevlar braid is wrapped around the tubing, providing structural support without compromising PTFE’s inertness.

Structure:

- Inner smooth or convoluted PTFE tube

- Braided mesh (externally or between layers)

Applications:

- Hydraulic lines

- Hot oil transfer hoses

- High-pressure steam lines

Benefits:

- Crush resistant and kink-proof

- Withstands higher internal pressures (up to 6,000 psi)

- Long flex life even in continuous movement

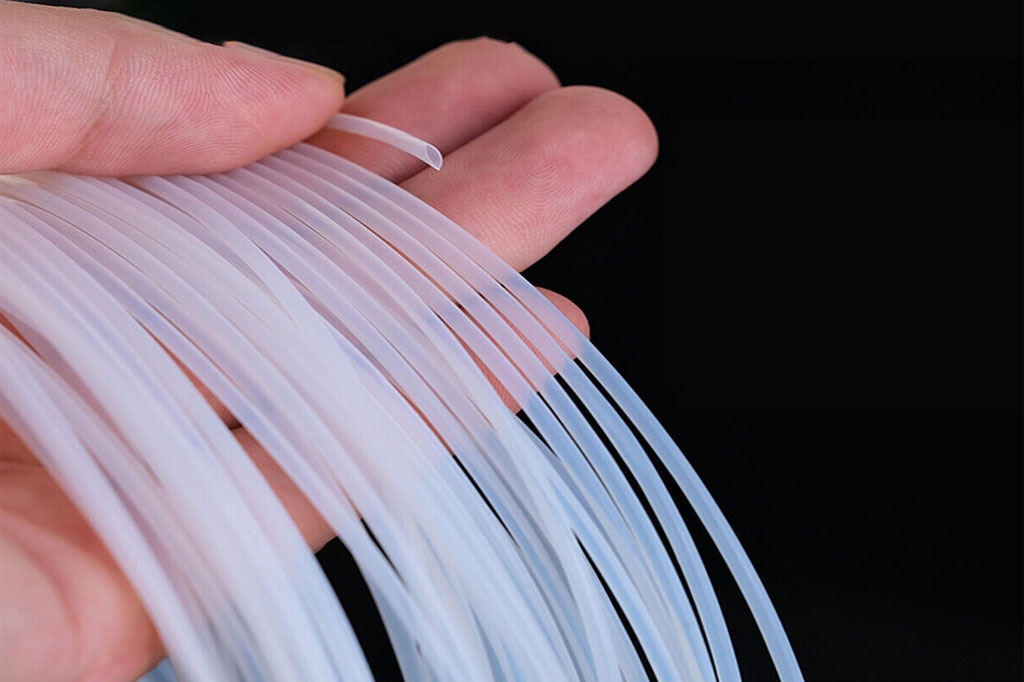

10. PTFE Microbore and Capillary Tubing

Microbore tubing features an extremely small inner diameter, usually under 1 mm. It’s designed for precise flow control and minimal dead volume.

Tolerances:

- ID as small as 0.1 mm

- Extremely high dimensional accuracy

Applications:

- High-Performance Liquid Chromatography (HPLC)

- Gas chromatography (GC)

- Microfluidic chip systems

Advantages:

- Smooth bore for reduced turbulence

- Inert and non-reactive for analytical precision

- Custom coil lengths available for compact instruments

Summary Comparison Chart

| Variant | Flexibility | Pressure Rating | Purity | Special Features |

|---|---|---|---|---|

| Natural PTFE | Medium | Medium | High | General-purpose |

| Colored PTFE | Medium | Medium | Moderate | Visual coding |

| Convoluted PTFE | High | Low | Moderate | Dynamic movement |

| Heat Shrink PTFE | Low | Medium | High | Sealing and insulation |

| Dual-Layer PTFE | Medium | Medium | High | Hybrid performance |

| Spiral PTFE | High | Low | Moderate | Retractability |

| Filled PTFE | Low-Medium | High | Low | Strength & wear resistance |

| ePTFE | High | Low | Moderate | Porous & compressible |

| Braided PTFE | Medium | Very High | Moderate | Pressure resistant |

| Microbore PTFE | Low | Low | Very High | Analytical precision |