Coatings play a critical role across various industries, protecting surfaces from wear, corrosion, and chemical damage while imparting functional properties such as low friction or enhanced thermal resistance.

Two of the most popular coating technologies today are polytetrafluoroethylene (PTFE) coatings and ceramic coatings. Each offers unique advantages and limitations, making them suitable for different applications.

This article provides a detailed comparison of PTFE and ceramic coatings, exploring their composition, performance characteristics, typical uses, and how to choose the right option for specific needs.

What Is PTFE Coating?

PTFE coatings are created by applying a suspension of PTFE particles (often in a liquid binder) onto a substrate, then baking it at high temperatures (typically between 350 °C and 400 °C). During baking, the binder volatilizes, allowing the PTFE particles to sinter and form a continuous, uniform film on the substrate’s surface.

Key Properties

- Low Coefficient of Friction: PTFE features an exceptionally low coefficient of friction (approximately 0.05 to 0.20), offering outstanding non-stick properties. This low friction makes it ideal for applications where sliding contact or food release is required.

- Chemical Inertness: PTFE is highly resistant to almost all chemicals and solvents (except molten alkali metals and fluorinating agents), ensuring that the coated surface remains unaffected by harsh environments.

- Thermal Stability: PTFE coatings can operate continuously up to around 260 °C without significant degradation. Short-term excursions to slightly higher temperatures are possible, but prolonged exposure above 260 °C can cause decomposition (releasing toxic fumes).

- Electrical Insulation: With its high dielectric strength and breakdown voltage, PTFE serves as an excellent insulating material in electrical and electronic applications.

- Non-Wettability and Hydrophobicity: The surface energy of PTFE is extremely low, rendering it hydrophobic and resisting the adhesion of moisture, oils, and other contaminants.

Common Applications

- Cookware and Bakeware: Non-stick pans, griddles, and baking trays.

- Industrial Equipment: Bearings, slides, and seals where low friction is essential.

- Chemical Processing: Linings for pipes, tanks, and valves handling aggressive chemicals.

- Automotive and Aerospace: Release coatings for molding and assembly processes.

- Electrical Industry: Insulating layers on wires, cables, and printed circuit boards.

Advantages of PTFE Coating

- Superior Non-Stick Performance: Virtually no food or residue sticks, simplifying cleaning processes.

- Excellent Chemical Resistance: Suitable for highly aggressive environments.

- Low Friction: Reduces wear on moving parts and minimizes torque requirements.

- Good Electrical Insulation: Wide use in electrical and electronic components.

Disadvantages of PTFE Coating

- Limited Temperature Range: Continuous use above 260 °C is not recommended.

- Surface Hardness: PTFE is relatively soft (Mohs hardness ~2), making it prone to scratching and abrasion if improperly handled.

- UV Sensitivity: Long-term exposure to ultraviolet (UV) light can degrade PTFE and cause embrittlement.

- Adhesion Challenges: Special surface pretreatments (e.g., chromate conversion on aluminum) are often needed to ensure strong bonding between PTFE and metallic substrates.

What Is Ceramic Coating?

Ceramic coatings are composite layers composed of inorganic, non-metallic materials bonded together by metallic or ceramic binders. Typical processes include plasma spraying, thermal spraying, or chemical vapor deposition (CVD).

Common ceramics include aluminum oxide (Al₂O₃), zirconium oxide (ZrO₂), chromium oxide (Cr₂O₃), silicon carbide (SiC), and silicon nitride (Si₃N₄). The deposition technique determines the microstructure: plasma spraying results in lamellar splats, while CVD yields a more columnar structure.

Key Properties

- High Hardness and Wear Resistance: Ceramics often exhibit hardness values above 1,000 Vickers (HV), significantly higher than most metals and polymers. This hardness translates to excellent resistance against abrasive wear and surface scratching.

- Elevated Temperature Stability: Many ceramic coatings can withstand temperatures exceeding 1,000 °C for extended periods without degradation. For example, zirconia-based coatings remain stable up to around 1,200 °C, depending on composition.

- Corrosion and Oxidation Resistance: Ceramics inherently resist oxidation and many corrosive media, making them suitable for harsh environments, including high-temperature exhaust systems and chemical reactors.

- Thermal Barrier Properties: Low thermal conductivity (e.g., 1–2 W/m·K for zirconia) enables ceramic coatings to act as thermal barriers, protecting underlying substrates (e.g., turbine blades) from high-temperature gases.

- Electrical Insulation: Most ceramics are excellent electrical insulators, suitable for applications requiring dielectric properties.

Common Applications

- Aerospace: Thermal barrier coatings (TBCs) on turbine blades to increase engine efficiency.

- Automotive: Protective coatings on exhaust components, brake discs, and engine parts for heat and wear resistance.

- Industrial Machinery: Wear-resistant liners for pumps, valves, and bearings handling abrasive media.

- Electronics: Dielectric layers in microelectronics and high-voltage insulators.

- Medical Devices: Bioceramic coatings (e.g., hydroxyapatite) on implants to enhance osseointegration.

Advantages of Ceramic Coating

- Exceptional Wear and Abrasion Resistance: Resists harsh mechanical environments.

- High-Temperature Endurance: Functionality at temperatures far beyond PTFE’s limits.

- Thermal Barrier Performance: Protects substrates from rapid temperature changes and heat damage.

- Chemical Inertness: Resistant to most acids, bases, and solvents at moderate to high temperatures.

- Durability: Long service life under extreme conditions.

Disadvantages of Ceramic Coating

- Brittleness: Ceramics are inherently brittle; under impact or bending stresses, coatings can crack or spall.

- Complex Deposition Equipment: Requires specialized equipment (e.g., plasma spray torches, vacuum chambers) and skilled operators.

- Higher Cost: Material and process expenses tend to be higher compared to polymer-based coatings.

- Surface Roughness: Plasma-sprayed coatings often exhibit higher surface roughness, necessitating post-processing if a smoother finish is desired.

Detailed Comparison

| Property | PTFE Coating | Ceramic Coating |

|---|---|---|

| Material Type | Synthetic fluoropolymer (Teflon®) | Inorganic ceramic compounds (e.g., Al₂O₃, ZrO₂, SiC) |

| Friction Coefficient | Very low (0.05–0.20) — excellent non-stick | Moderate (0.4–0.8) — not inherently non-stick |

| Thermal Resistance | Up to ~260 °C continuous | 600 °C to 1,200 °C+ depending on material |

| Chemical Resistance | Excellent — resists most chemicals except molten alkali metals | Excellent — highly resistant, especially at elevated temperatures |

| Wear Resistance | Moderate — soft and prone to scratching | Excellent — very hard and abrasion-resistant |

| Electrical Insulation | Excellent dielectric properties | Excellent insulator |

| Surface Finish | Smooth, glossy, thin layer (5–25 μm) | Rougher, matte; may require grinding to smooth |

| Application Process | Spray + bake (oven curing) | Plasma spray, thermal spray, or chemical vapor deposition (CVD) |

| Adhesion | Requires surface treatment + primer | Grit blasting + mechanical bonding; bond coats often used |

| Flexibility | Somewhat flexible — can bend with substrate | Brittle — prone to cracking under impact or stress |

| Cost | Lower — inexpensive materials and equipment | Higher — expensive process and materials |

| Durability | Moderate — surface can wear or degrade over time | High — long-lasting even in extreme conditions |

| Environmental Concerns | Must be PFOA-free; can emit fumes if overheated | Generally inert; particles must be handled properly during application |

| Typical Applications | Cookware, seals, slides, electrical insulation, chemical tanks | Exhausts, turbines, pumps, valves, engine parts, aerospace components |

| Best For | Low-friction, non-stick, chemical resistance below 260 °C | High-temperature, high-wear, thermal barrier and chemical resistance environments |

1. Mechanical Durability

- PTFE: Soft and prone to scratching or gouging if subjected to abrasive contact. While adequate for light-duty sliding applications, it cannot withstand high-pressure abrasive wear.

- Ceramic: Extremely hard and resistant to abrasion, making it suitable for applications where components face sand, grit, or metal-on-metal contact.

2. Thermal Resistance

- PTFE: Stable up to ~260 °C continuously. At temperatures above this threshold, thermal degradation begins, leading to reduced mechanical and non-stick properties.

- Ceramic: Remains stable at temperatures ranging from 600 °C to over 1,200 °C, depending on the ceramic chosen. These materials are well-suited for high-temperature environments such as turbine components and exhaust systems.

3. Chemical Resistance

- PTFE: Inert to almost all chemicals, including strong acids, alkalis, and organic solvents. Cannot be attacked by corrosive media at typical process temperatures.

- Ceramic: Also highly resistant to chemical attack. Certain ceramics (e.g., alumina, zirconia) withstand aggressive chemicals at elevated temperatures, though some specialized ceramics are tailored to resist specific corrosive environments.

4. Friction and Non-Stick Behavior

- PTFE: Exhibits one of the lowest coefficients of friction known among solids (≈0.05–0.20). This makes it the gold standard for non-stick applications like cookware, sliders, and seals.

- Ceramic: Coefficient of friction varies by ceramic type but generally ranges from 0.4–0.8 in sliding contact. Not considered non-stick; typically used for wear protection rather than release properties.

5. Surface Finish and Aesthetics

- PTFE: Can produce very smooth, glossy surfaces. Commonly applied in multiple layers (primer, intermediate, top) to achieve uniform thickness (5–25 μm) and a visually pleasing finish.

- Ceramic: Plasma-sprayed ceramic coatings exhibit a characteristic rough, matte appearance. Surface roughness values (Ra) commonly lie between 5–15 μm. Post-spray treatments (grinding, polishing) are needed if a smoother finish is required.

6. Adhesion and Pre-Treatment

- PTFE: Requires aggressive surface pre-treatment to achieve sufficient adhesion. Typical methods include chromate conversion coatings on aluminum or grit blasting with alumina, followed by a primer layer. Improper preparation can lead to delamination or flaking.

- Ceramic: Substrates are often grit blasted to create mechanical anchoring for the molten ceramic splats during deposition. Bond coats (e.g., NiCrAlY) are sometimes used to improve adhesion between ceramic topcoats and metallic substrates, especially when thermal expansion mismatches are a concern.

7. Cost Considerations

- PTFE: Generally lower material cost and simpler application equipment (spray booths and ovens). For standard non-stick applications, PTFE coatings remain cost-effective.

- Ceramic: Higher initial investment due to sophisticated equipment (e.g., plasma spray systems) and operating costs (energy input, inert gas). Material costs for high-performance ceramics (e.g., yttria-stabilized zirconia) can be significantly higher.

8. Environmental and Health Factors

- PTFE: Historically, some PTFE formulations contained PFOA (perfluorooctanoic acid) or similar processing aids, which raised environmental and health concerns. Modern regulations have led to PFOA-free PTFE processes. During high-temperature degradation (>260 °C), PTFE can emit toxic fumes (e.g., perfluoroisobutylene).

- Ceramic: Generally inert and nontoxic, both during service and upon wear. During plasma spraying, airborne particulates and aerosolized metals require adequate filtration and respiratory protection. Spent ceramic powders and overspray must be handled as industrial waste but pose fewer long-term environmental hazards compared to PFAS-containing polymers.

Applications and Suitability

Cookware and Kitchenware

- PTFE: The ubiquitous choice for non-stick pans, baking sheets, and appliances. Provides superior food release and easy cleaning. Users appreciate the low-maintenance nature of PTFE-coated cookware.

- Ceramic: “Ceramic non-stick” coatings have gained popularity as PFOA-free alternatives. These are often silicone-based paints with inorganic fillers, rather than true plasma-sprayed ceramics. True ceramic cookware coatings (e.g., silicon nitride films) offer some non-stick performance but may not match PTFE’s slipperiness. They excel in scratch resistance but can lose non-stick properties if overheated.

Automotive and Aerospace

- PTFE: Used as bearing and seal coatings in components where lubrication is challenging. Selected for its low friction in sliding contacts (e.g., throttle plates, actuator bushings). However, PTFE’s limited temperature range can restrict use in exhaust-facing parts.

- Ceramic: Widely applied as thermal barrier coatings on turbine blades, exhaust valves, piston crowns, and brake discs. Their ability to withstand up to 1,200 °C allows engines to operate at higher combustion temperatures, improving efficiency and reducing emissions.

Industrial Machinery

- PTFE: Coatings on screws, pumps, and mixers in chemical plants to prevent fouling and resist corrosion. Ideal where product release is paramount or seal efficacy must be maintained in aggressive media.

- Ceramic: Liners in slurry pumps, valve seats, and wear plates in mining and mineral processing. Chutes, hoppers, and other high-wear surfaces also benefit from ceramic’s hardness.

Medical and Electronics

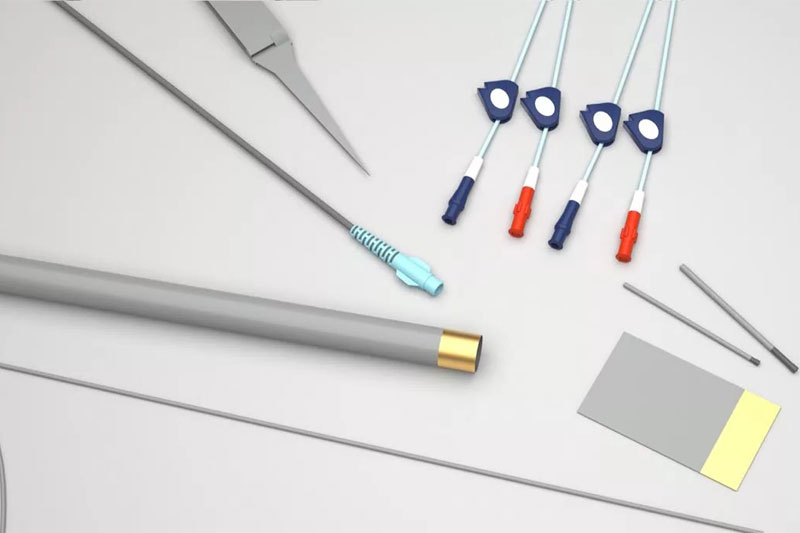

- PTFE: Catheters, stents, and surgical tools utilize PTFE coatings for biocompatibility and reduced tissue adhesion. In electronics, PTFE films insulate cables and connectors.

- Ceramic: Bioceramic coatings such as hydroxyapatite promote bone growth on implant surfaces. PZT (lead zirconate titanate) coatings appear in actuators and sensors. In electronics, dielectric ceramic layers enable high-voltage components and RF devices.

How to Choose Between PTFE and Ceramic Coatings

When selecting a coating, consider the following factors:

Operating Temperature

- Below 260 °C and requiring non-stick or low-friction properties? PTFE is ideal.

- Above 300 °C or in direct contact with high-temperature gases? Choose ceramic.

Mechanical Wear Environment

- Applications with light sliding contact or minimal abrasion can use PTFE.

- Aggressive abrasion, particulate flow, or cavitation demands ceramic.

Chemical Exposure

- Both coatings resist chemicals; however, extremely high-temperature chemical exposure favors ceramic.

Desired Friction Level

- Ultra-low friction/complete non-stick: PTFE.

- Moderate friction acceptable but durability under abrasive loads: Ceramic.

Surface Finish Requirements

- Smooth, glossy surface without post-processing: PTFE.

- Rough, matte finish (or one that will undergo post-deposition grinding): Ceramic.

Budget Constraints

- Lower upfront cost and simpler application: PTFE.

- Higher initial and operational costs but longer service life in extreme conditions: Ceramic.

Environmental and Regulatory Considerations

- Ensure PTFE processes are PFOA-free.

- Ceramics pose fewer environmental risks but require proper handling of particulates during deposition.

Conclusion

PTFE and ceramic coatings each occupy unique niches in the coating technology landscape.

PTFE excels in low-friction, non-stick, and chemical-inertness applications, making it a go-to solution for cookware, seals, and electrical insulation up to moderate temperatures.

In contrast, ceramic coatings stand out in high-temperature, high-wear, and corrosion-resistant scenarios, playing critical roles in aerospace engines, automotive exhaust systems, and industrial machinery facing severe abrasive environments.