Fluoropolymers are a group of high-performance plastics known for their exceptional chemical resistance, thermal stability, and non-stick properties.

Among them, polytetrafluoroethylene (PTFE), fluorinated ethylene propylene (FEP), perfluoroalkoxy (PFA), and polyvinylidene fluoride (PVDF) stand out as the most widely used grades. Although they share the hallmark fluoropolymer traits of inertness and durability, each presents unique strengths and limitations.

This article delves into the chemistry, physical properties, processing methods, applications, and selection criteria for PTFE, FEP, PFA, and PVDF, guiding engineers, materials scientists, and product designers toward the optimal material choice.

1. Polytetrafluoroethylene (PTFE)

Discovered by accident in 1938 by a DuPont chemist, PTFE is the most well-known fluoropolymer, famously marketed under the brand name Teflon.

Chemical Structure & Properties

- Chemistry: PTFE consists of a carbon backbone fully saturated with fluorine atoms (–[CF₂–CF₂]ₙ–).

- Thermal Stability: It exhibits one of the highest melting points among thermoplastics (327 °C) and maintains structural integrity up to 260 °C in continuous use.

- Chemical Resistance: Its all-fluorine surface renders PTFE virtually inert to virtually all chemicals, including strong acids, bases, and solvents.

- Surface Energy: Outstandingly low (≈0.018 J/m²), giving PTFE excellent non-stick and anti-fouling characteristics.

- Electrical Insulation: Dielectric constant ≈2.1 and loss tangent <0.0002 at 1 MHz, making it ideal for high-frequency insulation.

Processing & Limitations

- Processing: PTFE cannot be melt-processed; it is formed by compression molding, ram extrusion, or paste extrusion followed by sintering.

- Limitations: Its high melt viscosity precludes injection molding. Mechanical properties are moderate: tensile strength ≈25–35 MPa and elongation-at-break ≈200–300%. It exhibits significant cold flow (creep) under load.

Typical Applications

- Seals, gaskets, and O-rings in chemical processing

- Bearings and bushings where low friction is critical

- Wire and cable insulation for aerospace and telecom

- Non-stick coatings for cookware

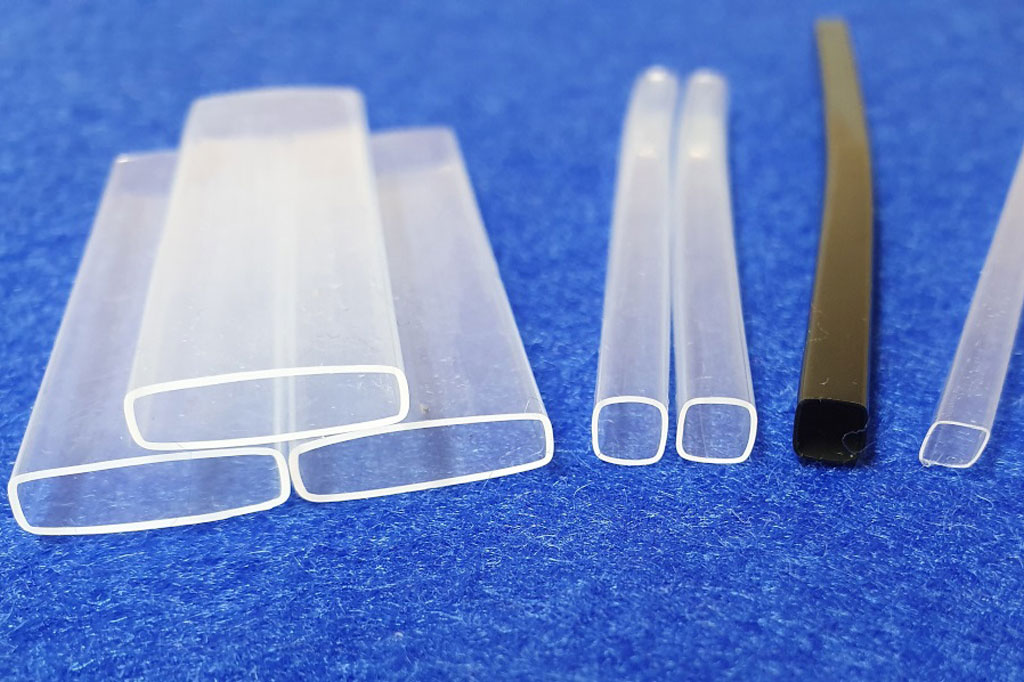

2. Fluorinated Ethylene Propylene (FEP)

FEP is a melt-processable copolymer of hexafluoropropylene and tetrafluoroethylene. It retains many of PTFE’s chemical properties but allows for easier fabrication through traditional thermoplastic processes.

Chemical Structure & Properties

- Chemistry: A copolymer of tetrafluoroethylene (TFE) and hexafluoropropylene (HFP), denoted –[CF₂–CF₂]ₓ–[CF₂–C(F)(CF₃)]ᵧ–.

- Thermal Stability: Melt processable; melting point ≈260 °C with continuous service up to 200–205 °C.

- Chemical Resistance: Excellent, closely matching PTFE, though slightly less resistant toward a few extremely aggressive media.

- Optical Properties: Translucent to transparent, with low refractive index, beneficial for optical applications.

- Electrical Insulation: Good dielectric properties (εᵣ≈2.1, tan δ≈0.0004).

Processing & Advantages

- Processing: Can be melt-processed by injection molding, extrusion, and blow molding, thanks to its lower melt viscosity relative to PTFE.

- Advantages: Combines PTFE-like inertness with ease of fabrication into complex shapes. Offers smoother surfaces and tighter dimensional tolerances.

Typical Applications

- Linings for pipes, hoses, and tanks in chemical plants

- Coatings on wires and cables

- Thin films for photolithography and semiconductor processing

- Tubing and fittings for pharmaceutical and biotech industries

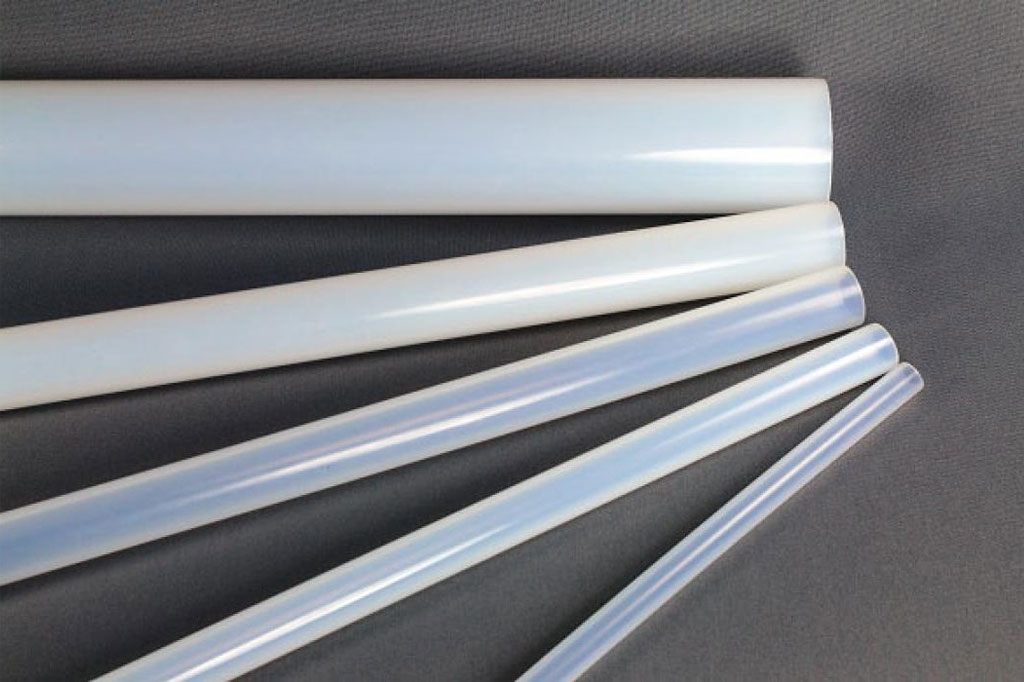

3. Perfluoroalkoxy (PFA)

PFA is another copolymer similar to PTFE but includes perfluoroalkoxy side chains. It combines the properties of PTFE with greater thermal stability and processability than FEP.

Chemical Structure & Properties

- Chemistry: A copolymer of tetrafluoroethylene and perfluoroalkyl vinyl ethers (PAVE), –[CF₂–CF₂]ₓ–[CF₂–C(F)(ORf)]ᵧ–.

- Thermal Stability: Melting point ≈305 °C, continuous service up to 260 °C—highest among melt-processable fluoropolymers.

- Chemical Resistance: Virtually identical to PTFE and FEP, resisting all but elemental fluorine and molten alkali metals.

- Mechanical Properties: Better tensile strength (≈30–35 MPa) and elongation (≈200–300%) than FEP; minimal creep.

Processing & Benefits

- Processing: Fully melt-processable; suitable for injection molding, extrusion, and blow molding.

- Benefits: Exceptional weldability and fusion bonding, enabling large, complex shapes without adhesives. Superior clarity to FEP, with very low extractables—critical for semiconductor and pharmaceutical use.

Typical Applications

- Chemical reactor linings and vessels

- High-purity piping and fittings in semiconductor fabrication

- Valve seats, diaphragms, and seals in pharmaceutical equipment

- Linings for storage tanks handling hot corrosive media

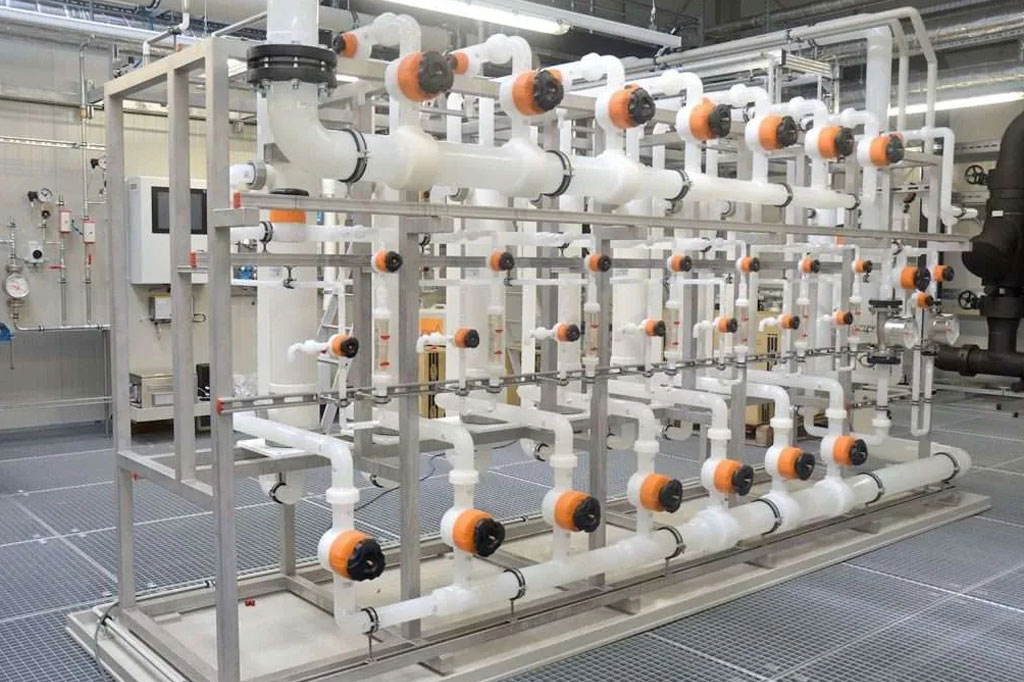

4. Polyvinylidene Fluoride (PVDF)

PVDF is a semi-crystalline thermoplastic fluoropolymer that, unlike the other three, contains hydrogen atoms in addition to carbon and fluorine. It is less chemically inert but has high mechanical strength and better processability.

Chemical Structure & Properties

- Chemistry: A semicrystalline thermoplastic composed of –[CH₂–CF₂]ₙ– units. Unlike fully fluorinated PTFE/PFA/FEP, PVDF contains hydrogen.

- Thermal Stability: Melting point ≈177 °C, continuous use up to 150–160 °C.

- Chemical Resistance: Excellent toward a wide range of acids, bases, and solvents, though less inert than PTFE-family fluoropolymers in the most aggressive media.

- Mechanical Properties: It exhibits a tensile strength of roughly 48–60 MPa, outstanding toughness, and exceptional abrasion resistance.

- UV & Radiation: Good UV resistance and resistance to gamma and X-ray sterilization—valuable for outdoor and medical applications.

Processing & Characteristics

- Processing: Easily processed by injection molding, extrusion, and melt casting.

- Characteristics: Exhibits piezoelectric and pyroelectric properties when suitably polarized; moderate surface energy supports better adhesive bonding relative to PTFE/FEP/PFA.

Typical Applications

- Pipes, valves, and fittings for water treatment and chlor-alkali systems

- Architectural panels and cladding exposed to UV/weathering

- Coatings for heat exchangers and tanks

- Sensors, actuators, and membranes leveraging its electroactive properties

5. Comparative Property Overview

| Property | PTFE | FEP | PFA | PVDF |

|---|---|---|---|---|

| Melting Point (°C) | 327 | 260 | 305 | 177 |

| Service Temp (°C) | –240 to +260 | –200 to +205 | –200 to +260 | –40 to +150 |

| Chemical Resistance | Superior | Near PTFE | Near PTFE | Excellent but lower |

| Processability | Sintering only | Melt-processable | Melt-processable | Melt-processable |

| Tensile Strength (MPa) | 25–35 | 20–30 | 30–35 | 48–60 |

| Elongation at Break (%) | 200–300 | 200–300 | 200–300 | 50–300 |

| Surface Energy (mJ/m²) | ≈18 | ≈20 | ≈20 | ≈38 |

| Dielectric Constant (1 MHz) | ≈2.1 | ≈2.1 | ≈2.1 | ≈8–11 |

| UV Stability | Poor | Poor | Poor | Excellent |

| Cost | Highest | High | Higher than FEP | Moderate |

6. Application Considerations & Selection Guide

- Extreme Chemical Resistance & High Temperatures

- Choose PTFE when the primary requirement is absolute inertness and peak thermal stability, and part complexity is low (e.g., seals, bearings, simple shapes).

- Complex Shapes & Tight Tolerances

- Choose FEP or PFA if you need melt-processable fluoropolymers with excellent chemical resistance in complex geometries or large components.

- Use PFA over FEP when higher temperature limits, superior mechanical strength, or ultra-high purity (low extractables) are critical.

- Mechanical Loads & Abrasion Resistance

- Choose PVDF when significant mechanical strength, toughness, abrasion resistance, or UV/weatherability are required—commonly in structural components, coated surfaces, or outdoor applications.

- Electrical & Optical Applications

- PTFE remains the go-to for demanding RF/microwave insulation and non-stick surfaces.

- FEP and PFA provide translucent films and coatings for semiconductor photolithography or chemical analysis tubing.

- PVDF offers unique piezoelectric/pyroelectric capabilities for sensors and actuators.

- Cost Sensitivity

- PVDF generally offers the lowest material cost among these fluoropolymers, followed by FEP, PFA, and finally PTFE as the most expensive.

7. Conclusion

PTFE, FEP, PFA, and PVDF each occupy distinct niches within the fluoropolymer family. PTFE excels in chemical inertness and thermal endurance but at the expense of complexity in fabrication. FEP and PFA bridge the gap by combining PTFE-like performance with melt-processability, making them ideal for intricate components and high-purity applications. PVDF, while less chemically inert, delivers superior mechanical strength, abrasion resistance, UV stability, and unique electroactive properties, often at a lower cost.

By carefully weighing service temperature, chemical environment, mechanical demands, processing methods, and budget, engineers can select the fluoropolymer that best aligns with their application requirements, ensuring optimal performance and longevity.